US-based 3PL Netrush automates order picking and replenishment

Netrush is a US-based third-party logistics company that has been operating for more than 17 years. It offers integrated logistics services for ecommerce retailers, in addition to other services such as data analytics and performance marketing. Their main warehouse facility in Kentucky ships out 20,000 orders per day for a variety of brands including Duracell, Leatherman and Yakima. During peak season shipping volumes grow by 4-5x.

Challenges

Netrush wanted to increase their competitiveness by reducing costs and streamlining their operations. They were looking for an automated order picking solution that was easy to scale, so they could start with a few robots and expand it on-demand as they added new customers into the system.

Solution

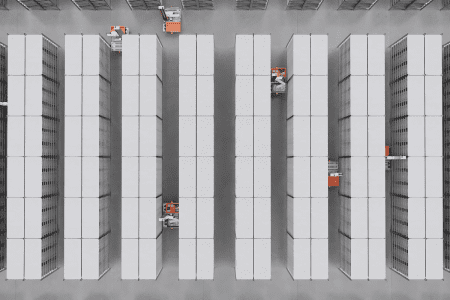

Netrush installed Brightpick Retriever robots, a Goods-to-Person solution for automated order picking and replenishment. The robots quickly retrieve totes from storage and transport them to an ergonomically-designed human picking station. Brightpick Retrievers also automate stock replenishment and dynamic slotting.

The entire installation took just six weeks, of which four were spent on integrating with Netrush’s WMS and two were for on-site installation. Netrush can easily boost capacity in a matter of days by simply adding additional shelving and robots; Brightpick robots work with standard shelving and do not require any fixed guidance systems such as QR codes.

“Brightpick was super easy to install. [The solution] was up in a matter of weeks. We thought a lot about scalability as we wanted to be able to grow. Adding on to this is almost like a Lego set, you just keep adding and adding.”

Brian Birch, Chief Supply Chain Officer at Netrush

The current solution is designed for 200 picks per hour with one human picking station. In the future, Netrush will be able to upgrade their picking station to have up to four tote presentations at the same time, which would boost volumes to more than 300 presentations and 500 picks per hour without adding labor. Netrush will also have the ability to upgrade their robots to Brightpick Autopicker, which would boost throughput even more.

Netrush purchased the solution via a robots-as-a-service (RaaS) pricing model, which meant they did not have to invest any capital upfront and could spread the cost out over several years, in line with their customer contracts.

“We love the cost structure. You can rent these robots like a SaaS-type service. And [we] can also add on to this as much as we want.”

Brian Birch, Chief Supply Chain Officer at Netrush

Results

Netrush increased their picking speeds and saw a 3-4x improvement in labor productivity using Brightpick Retrievers. This enabled Netrush to onboard more customers and offer additional services such as kitting and bundling, which would otherwise be too labor intensive.

“We saw almost a 4x increase in picking and packing [thanks to Brightpick]. This unlocked a lot of opportunities for our customers. We’re now able to offer kitting and bundling that’s very labor intensive that we just weren’t able to offer before. All this translates into happier customers and, of course, lower costs.”

Brian Birch, Chief Supply Chain Officer at Netrush

Netrush reallocated the labor it saved to other tasks such as packout and inbound. The solution’s ease-of-use also made onboarding new employees a lot easier and reduced picking errors and lost inventory.

“The picking and decanting process is super easy. It only takes about 2 hours to train on and after that you can usually leave the person by themselves.”

Jada Daniels, Shift Lead at Netrush

Brightpick provided a scalable solution that enabled Netrush to:

- Automate storage, retrieval and putaway

- Reduce labor for picking and replenishment by 75% (from four people to one)

- Achieve 200 picks per hour, with the option to increase volumes up to 500 picks per hour in the future without adding labor

- Double storage density

About Brightpick

Brightpick is a leader in AI-powered robotic solutions for warehouses. The company’s multi-purpose AI robots enable warehouses of any size to fully automate order picking, buffering, consolidation, dispatch, and stock replenishment. The award-winning Brightpick solution takes just weeks to deploy and allows companies to keep their warehouse labor to a minimum. With offices in the US and Europe, Brightpick has more than 250 employees and hundreds of AI robots deployed with customers.