3 ways to unlock higher ROI using mobile robots for order fulfillment

A growing number of companies are deploying robots in their distribution centers. According to a recent survey, 37% of companies already have some robots or automation in their facilities and a further 43% plan to add them within the next three years.

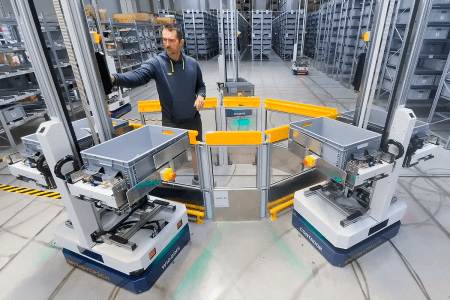

Mobile robots have boosted the market uptake of automation by enabling solutions that are more flexible and easier to install. They account for a double-digit market share in the automated fulfillment market and are forecast to grow by 30-40% per year until 2027, according to Interact Analysis.

When it comes to selecting automation, ROI is cited as the top consideration among buyers. Below are are three ways in which mobile robots unlock higher ROI from automation:

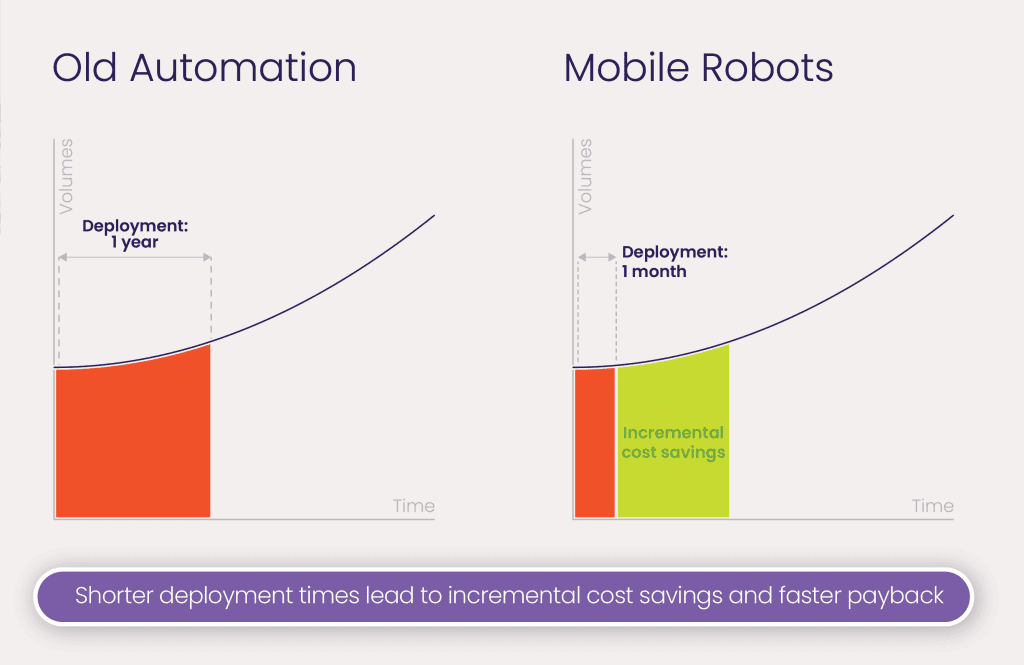

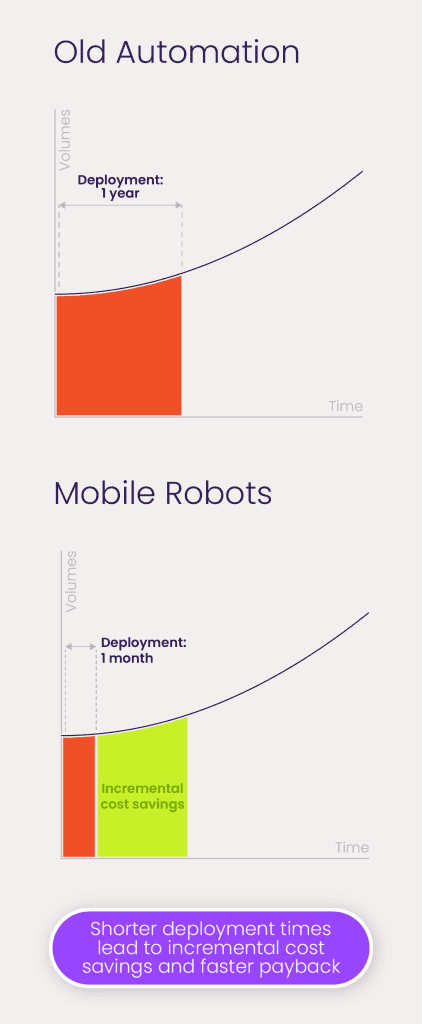

1. Shorter deployment times lead to faster payback

Complexity and lead time of deployment varies by solution. Installing automation requires not just hardware but also software integration, operational ramp-up and sometimes even facility modifications.

Mobile robot solutions, with their faster and simpler installation process, enable businesses to tap into the benefits of automation sooner. In most cases they do not require fixed infrastructure or conveyors and work with standard shelving and totes. Therefore companies can typically deploy these solutions in a matter of weeks without interrupting their ongoing operations. This enables customers to start realizing the benefits of automation sooner, which leads to a faster payback and a higher ROI.

By contrast, complex systems that require fixed infrastructure, conveyors, or engineered racking take months or even years to install. This extended timeline can be a significant drag on ROI because it delays the time to value and causes companies to miss out on the benefits of automation for longer. Extended deployment times can also lead to lost revenue if operations are paused or expansion plans are put on hold while the automation is being deployed.

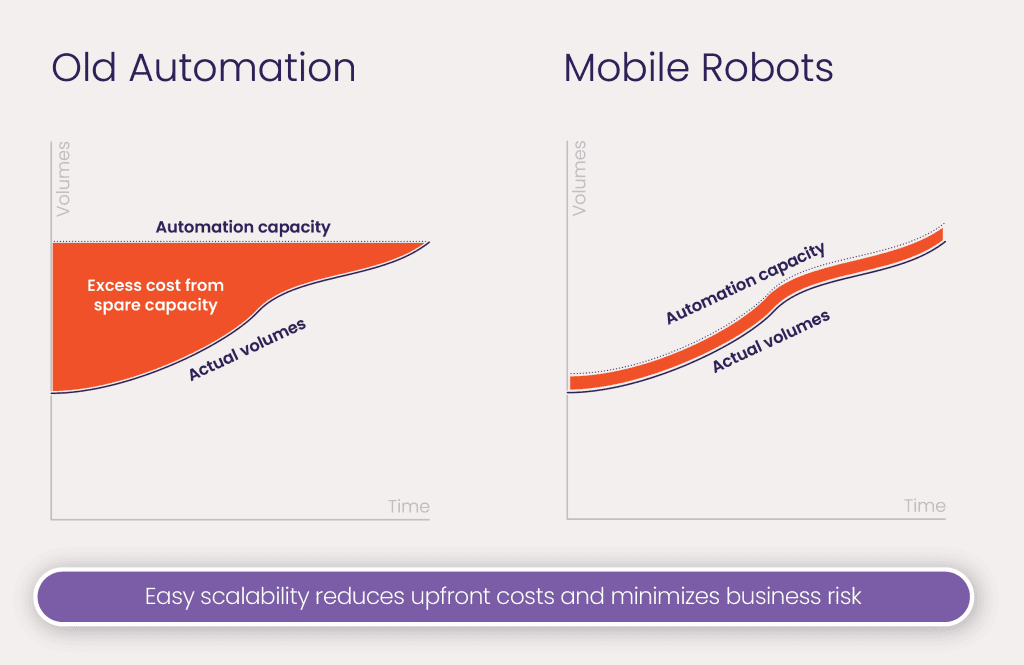

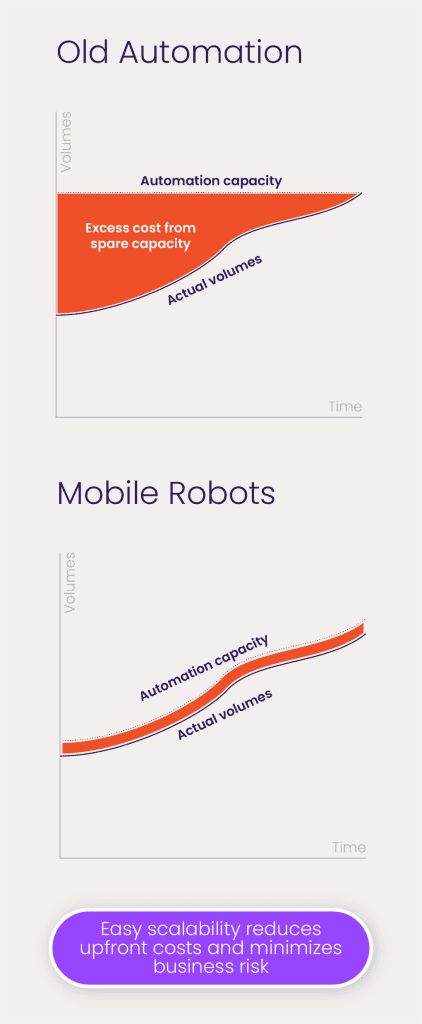

2. Easy scalability reduces upfront costs

Automation systems are always designed for a fixed volume, which necessitates forward planning to ensure operations can accommodate future growth.

Solutions using mobile robots can typically be scaled with minimal effort by simply adding additional robots and shelving. Companies can scale throughput gradually, in-line with their operating needs and revenues, which enables them to reduce upfront cost, minimize business risk and increase ROI.

While theoretically any type of automation can be scaled, the associated logistical challenges, costs and time render some systems practically non-scalable. Even modular solutions like cube storage still require fixed infrastructure like grids and conveyors, as well as potential building modifications, which makes them difficult to scale.

Consequently, warehouses are often forced to install automated systems that are designed for higher future volumes. This increases upfront costs and reduces ROI as spare automation capacity sits underutilized. Moreover, businesses always face the risk that volumes grow less than expected, in which case they’ve overpaid for a bloated system that is not being fully utilized.

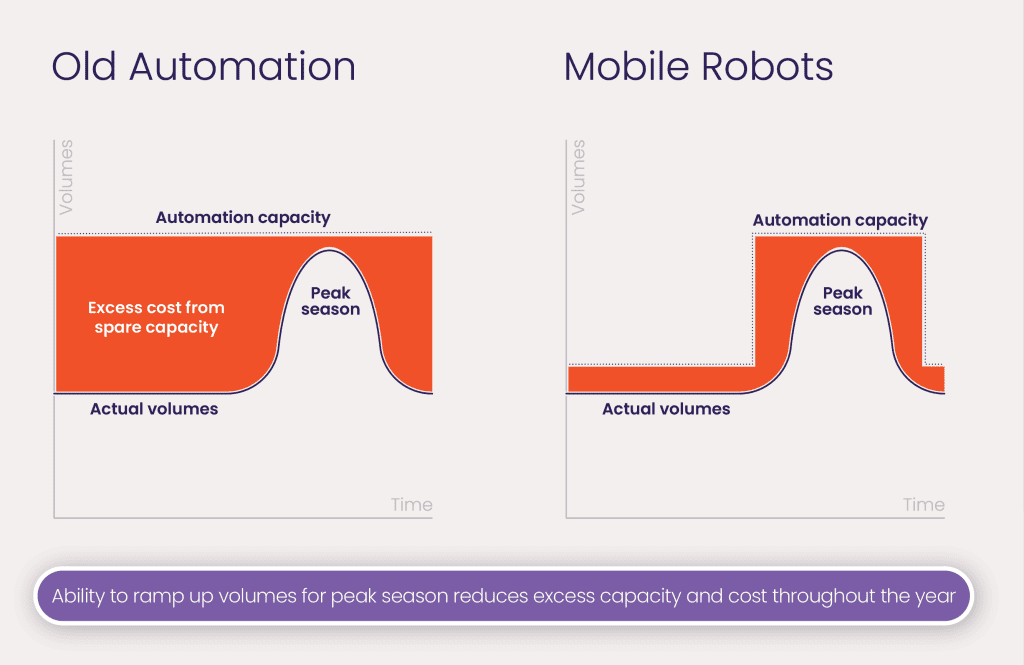

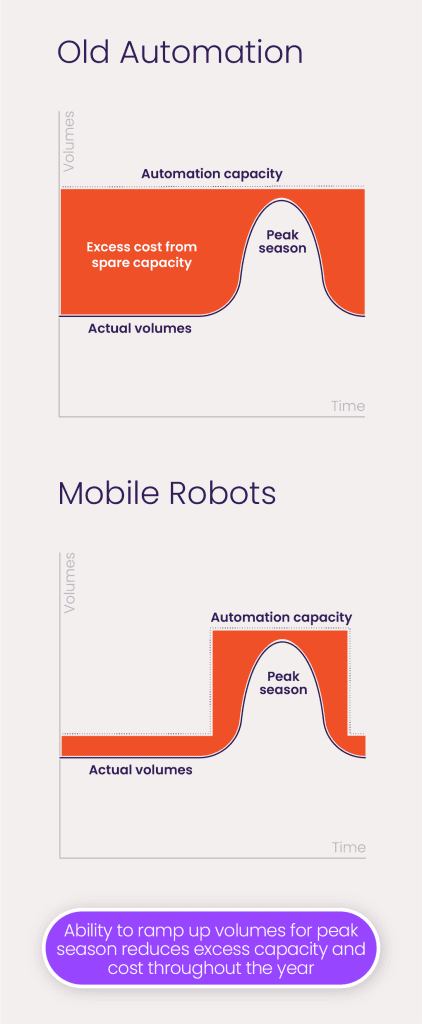

3. Ability to ramp up volumes for peak seasons optimizes capacity year-round

To mitigate business risk, automation must meet operational demands all year round. However designing an automated system for peak demand will inevitably result in underutilization during slower periods.

Mobile robots are typically easy to add to a solution once it is operational. Many mobile robot providers also offer short-term leasing options that enable fulfillment centers to increase volumes during peak season. This arrangement lets companies manage peak demand without having to maintain excess capacity throughout the year, which reduces cost and boosts ROI.

By comparison, most other automated systems cannot be ramped up for just a few months due to the high cost and complexity involved. This means companies must build the system for peak volumes, or find other means to manage peak seasons, for example with temporary labor. This effect is felt most by businesses with sharp and short-lived demand surges, such as many Q4-focused retailers, who risk footing the bill for automation capacity to sit idle for most of the year (or hiring expensive short-term labor for peak seasons).

In Summary

Mobile robots offer a distinct set of advantages for companies looking to automate their order fulfillment. Their fast deployment times and easy scalability allow businesses to reduce initial capital outlays, mitigate the risk of over-investment and accelerate time to value. These advantages contribute to a superior ROI, making mobile robots an increasingly popular choice in the automated fulfillment sector.

To see a concrete example of how mobile robots have delivered benefits in a real-world scenario, check out our case study on how one of Europe’s largest online grocers automated their order fulfillment with Brightpick.

About Brightpick

Brightpick is a leader in AI-powered robotic solutions for warehouses. The company’s multi-purpose AI robots enable warehouses of any size to fully automate order picking, buffering, consolidation, dispatch, and stock replenishment. The award-winning Brightpick solution takes just weeks to deploy and allows companies to keep their fulfillment labor to a minimum. Headquartered near Cincinnati, Ohio, Brightpick has more than 250 employees and hundreds of AI robots deployed with customers across the U.S. and Europe. For more information, contact us here.