E-Grocery

Make e-grocery

profitable

Improve profitability and offer customers better prices by reducing your fulfillment costs

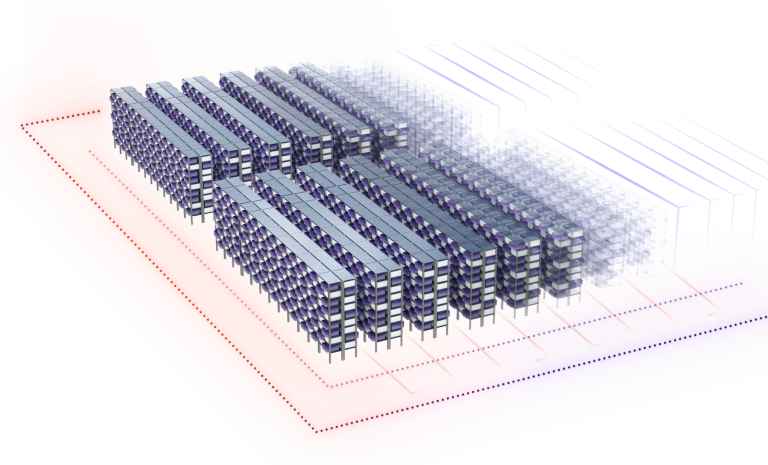

Easily automate order picking, consolidation and dispatch using our AI warehouse robots

Why e-Grocers need automation

Common challenges for e-grocers

- Lack of profitability in online sales High picking and last mile costs hurt profitability

- Demanding customers Demands for faster delivery, added convenience and more delivery slots during peak hours

- Complex supply chain High volumes and multiple picking zones increase operational complexity

- Expensive labor Poor availability and high cost of warehouse labor limits growth and profitability

- High error rates Picking errors reduce customer satisfaction

How Brightpick helps

- Minimizes labor requirements

- Cuts fulfillment costs

- Eliminates human picking errors

- Speeds up order picking

- Increases volumes without adding footprint

- Increases customer and employee satisfaction

- Enables easy scalability and more shifts

of grocers rate “Improve picking efficiency” as their #1 profitability lever

How it works:

Case study

Knuspr buffers and dispatches orders using Brightpick robots

Knuspr is one of Germany’s fastest-growing e-grocers.

The company has large average order sizes consisting of dozens of items per order. Its Munich fulfillment center holds more than 15,000 SKUs and has multiple picking zones to accommodate different types of products.

Knuspr was looking for a flexible robotic solution to automate the post-pick order buffer, consolidation and dispatch process.

With Brightpick, Knuspr was able to:

- Dispatch 20% more orders during peak hours

- Reduce labor for order consolidation and buffer to zero

- Extend warehouse operations to 20 hours per day

- Eliminate human errors from the dispatch process

“ We needed automation to make our operation more efficient, stable and scalable. We selected Brightpick because of the fast design and installation time, stable and high-performing product and robot-as-a-service pricing model. ”

Ales Malucha

Chief Automation Officer at Rohlik Group

Impact

How will Brightpick

make my job easier?

Pricing

Flexible pricing models

Brightpick is available through Robots-as-a-Service (RaaS), starting from just $1,900 per robot / per month.

RaaS transforms warehouse automation from a large upfront capital investment into a manageable monthly operating cost, which reduces financial risk, simplifies budgeting, and delivers immediate ROI.

Alternatively, the Brightpick solution is also available through a standard CapEx purchase.

Learn moreImprove profitability and offer customers better prices by reducing your fulfillment costs.

Improve customer satisfaction and reduce returns by eliminating human picking errors.

Store more inventory and fulfill more orders from the same warehouse footprint.

Minimize upfront costs and scale throughput gradually based on your needs.

Speed up order picking and fulfill more orders without adding footprint or labor.

Reduce supply chain risk and achieve 99.9% uptime with no single point of failure.