Germany’s economic downturn: how robotics can help e-grocers build resilience in a slowing economy

The dual shocks of high inflation and last year’s energy crisis have tipped Germany into a recession. Official data released in May 2023 revealed that output in Europe’s largest economy declined by 0.3% in the first quarter of this year, following a 0.5% contraction at the end of 2022. This is despite unemployment being close to all-time lows.

For e-grocers, the recession poses several challenges:

- Downtrading (the trade-down effect): consumers shift from higher-priced products to lower-priced alternatives, leading to lower revenues and margins.

- Higher last mile costs: high energy prices result in higher last mile costs and reduced margins for e-grocers. In addition, some consumers may become less inclined to pay for delivery.

- Cost inflation: the tight labor market leads to high wage inflation, which squeezes margins for grocers.

In this blog, we will explore how warehouse robotics can help German e-grocers overcome the challenges of lower consumer spending, higher last mile costs, and labor shortages during these uncertain times.

Challenge 1: Lower consumer spending and downtrading

With high economic uncertainty and inflation, consumers are reducing their spending and opting for lower-priced alternatives. 56% of consumers have shifted their spending in favor of lower-cost brands in 2023. This trend can be especially impactful in e-grocery, where prices are easily comparable across websites and competition is just one click away.

Solution: Increase customer retention

Increasing customer satisfaction can improve retention and make consumers less price-sensitive. One way to do this is to deliver orders faster and more accurately. Robotic warehouse solutions for order fulfillment can increase picking speeds and ensure on-time dispatch of orders. Robots also reduce picking errors and add consistency to the operation. By providing a seamless and reliable shopping experience, e-grocers can increase customer satisfaction, foster loyalty and retain more customers during times of economic stress.

Challenge 2: Increasing last mile costs

Last mile delivery costs e-grocers 8% of the order value on average, which can be a huge burden considering the low profit margins in the grocery industry. Last year’s energy crisis further increased these costs due to higher fuel prices. As a result, 86% of grocery retailers are dissatisfied with their online profitability. While many e-grocers have started charging consumers for delivery, passing on these higher costs in full can result in less competitive pricing and a loss of market share. As a result, e-grocers need to look for efficiencies elsewhere in their supply chain.

Solution: Offset high last mile costs with lower picking costs

To mitigate the excess costs from last mile delivery, e-grocers should focus on minimizing picking and warehousing costs. 79% of grocers cite “Improving picking efficiency” as their #1 profitability lever. Using robotics for order picking, e-grocers can cut costs for order picking by up to 50% by saving on labor costs, increasing the number of shifts per day and reducing picking errors.

Challenge 3: Labor shortages and wage inflation

Finding and retaining skilled workers is one of the biggest challenges faced by German businesses today. “Since Germany’s reunification, never have so many firms complained about labour shortages,” says Joerg Kraemer, Chief Economist at Commerzbank. A tight labor market also means workers have more power to demand big wage increases to compensate for inflation. Therefore grocers are not only struggling to fill vacancies, especially for physically-demanding jobs inside of warehouses, but they are also facing margin contraction from increasing wages.

Solution: Reduce labor needs

Robotics alleviates the pressure of labor shortages by reducing the reliance on manual labor. Robots can handle repetitive and time-consuming tasks such as picking and allow grocers to re-allocate their workforce for more productive and higher-value tasks. By leveraging automation, grocers can overcome labor shortages, reduce labor costs and increase profitability.

Conclusion

Robotic solutions are an effective way for e-grocers to overcome the challenges of lower consumer spending, higher last mile costs, and labor shortages. By implementing warehouse automation, e-grocers can optimize their operations and effectively navigate the ongoing economic downturn to position themselves for long-term success.

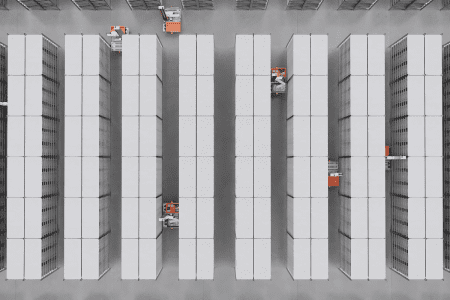

In response to these challenges, German e-grocers are seeking solutions that can drive efficiency and adaptability. One such solution that is gaining prominence is Brightpick, an end-to-end robotic solution for grocery order fulfillment. Brightpick offers e-grocers the ability to improve picking speed and accuracy, cut order fulfillment costs and reduce labor needs. By leveraging proprietary software, AI and robotics, Brightpick enables e-grocers to optimize their operations and navigate the economic downturn more effectively.

Knuspr.de, a fast-growing e-grocer in Germany, is installing Brightpick to automate their order fulfillment in Munich and Frankfurt. Read more here.