more

throughput

Brightpick

Autopicker

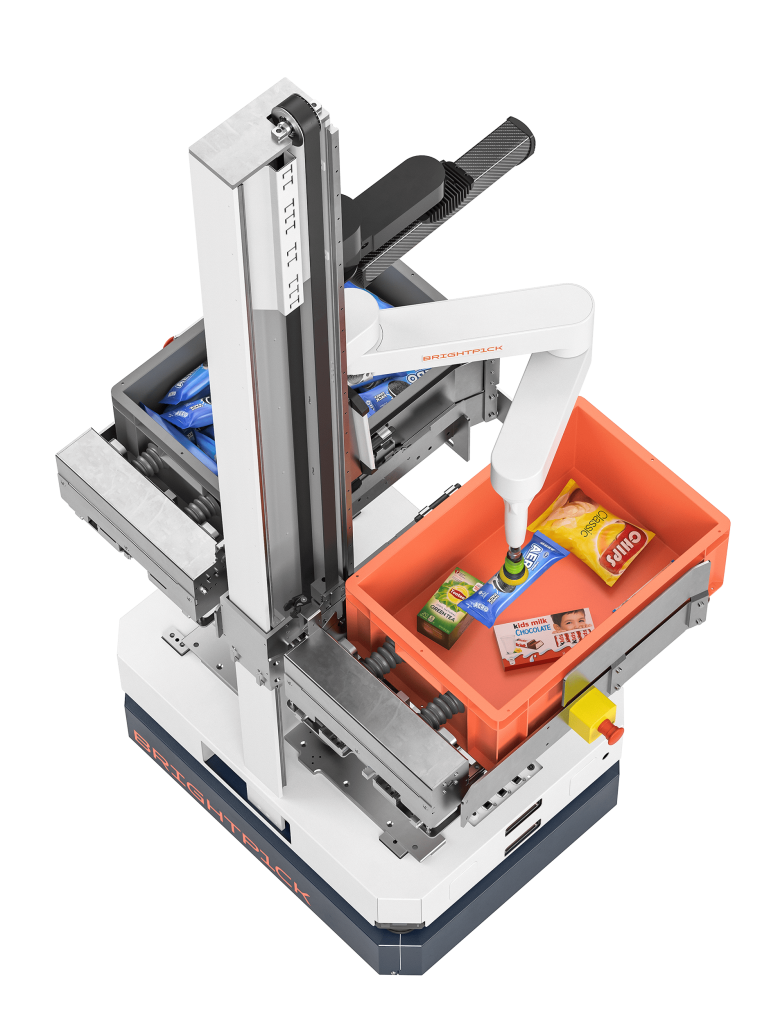

The world’s most advanced fulfillment robot powered by proprietary machine vision, AI and software.

ROBOTS

Autonomous mobile picking is here

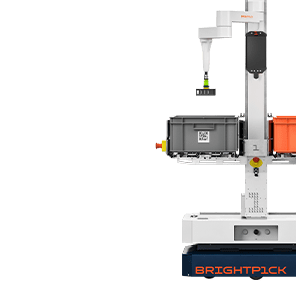

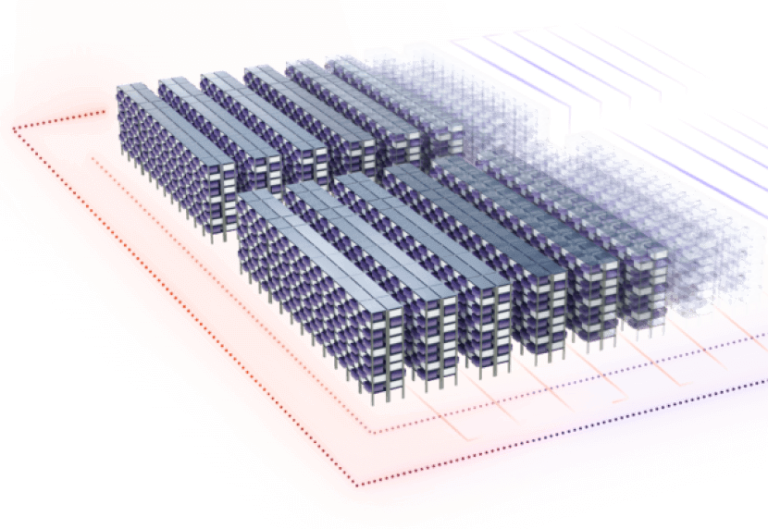

Brightpick Autopicker is the only mobile robot in the world that robotically picks and consolidates orders directly in the warehouse aisles. In addition to in-aisle robotic picking, Brightpick Autopicker can also be used for other important tasks such as Goods-to-Person picking, stock replenishment and dynamic slotting.

single points

of failure

STORAGE

Easy scalability, maximum flexibility

Brightpick Autopickers work with standard shelving and totes, enabling fast deployment and easy integration with any warehouse environment, including existing operations and mezzanines. The robots autonomously retrieve empty totes out of the system and dynamically slot new totes in.

month or less

to deploy

more storage

density

INTELLIGENCE

Reliable and accurate picking

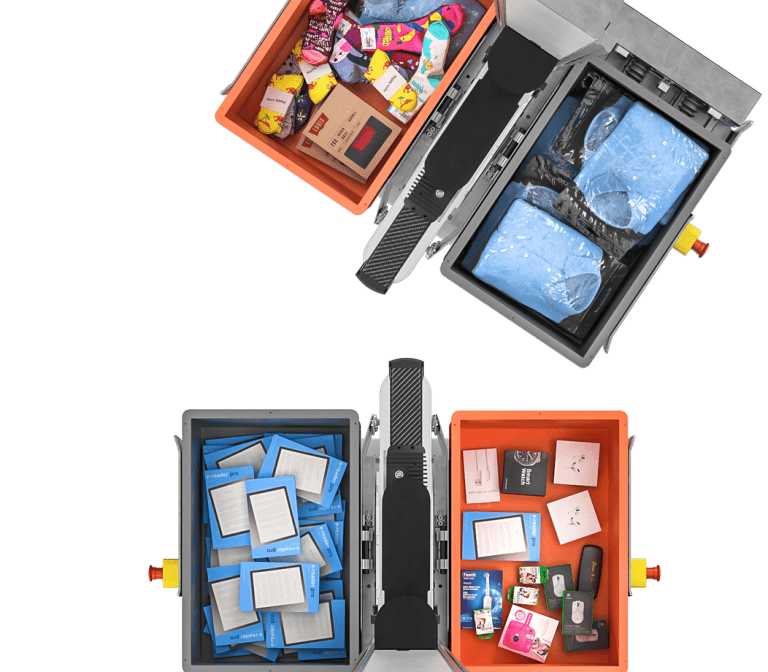

Brightpick Autopickers can reliably pick groceries, ambient and chilled groceries, packaged goods, cosmetics, electronics, pharmaceuticals, medical devices, polybagged apparel and more. Their advanced AI algorithms have been trained on more than 250 million picks to date and use machine learning to improve with each pick.

robotic picking

accuracy

robotic picks

completed

SOFTWARE

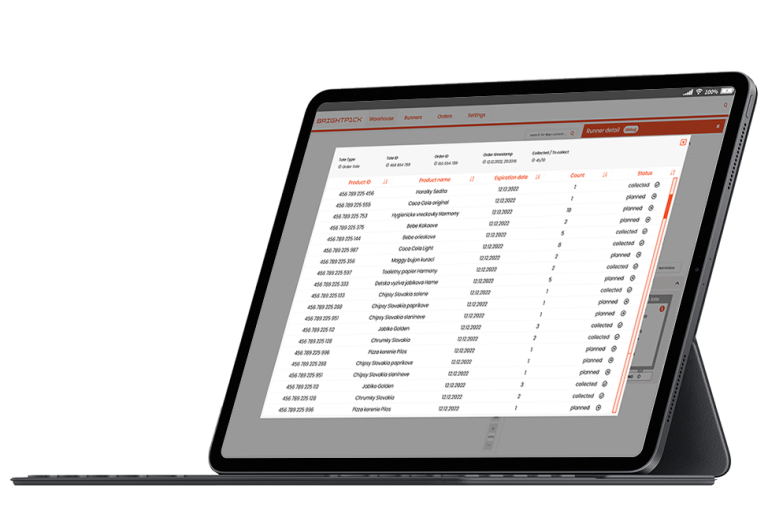

The brain that powers everything

The entire fulfillment process and Brightpick robot fleet, be it 10 or 100s of robots, is orchestrated and optimized by Brightpick Intuition software, including replenishment, storage, picking, order consolidation and dispatch. All you have to do is sit back with a cup of coffee and let Brightpick do the work.

ANALYTICS

Your very own digital warehouse

Brightpick Intuition integrates seamlessly with your WMS or ERP software. It allows you to remotely monitor and control all aspects of your fulfillment operations, tracking every robot, order, tote and SKU in real time. A simple and intuitive dashboard provides you with a detailed view of your warehouse performance at all times.

Software Features

Robots

Live view of all robots, including their status and workflows

Storage

AI-optimized dynamic slotting

based on item frequency

Path planning

Continuous pick-path optimization to

minimize travel distances

Maps

Use Autopickers to quickly create a digital map of your warehouse

Analytics

Monitor and visualize system performance metrics and KPIs

Inventory

Track all your inventory and

SKUs in one place

Our Solutions

Automate your order fulfillment to reduce labor,

cut costs and increase storage density.