How quickly will I get my money back if I spend $1M on automation?

“How much does it cost?” is typically the first question that comes to mind when evaluating warehouse automation. However, cost is only one part of the equation. Understanding the return on your investment is arguably even more important for building a compelling business case.

That’s why ROI is cited as the number one business factor by companies considering automation – above time to value, total cost of ownership, payback time and investment risk.

Calculating ROI can be complicated and time-consuming, but certain factors impact it more than others.

Here are the 5 most important drivers of ROI from warehouse automation:

1. Working shifts: more shifts equals higher ROI

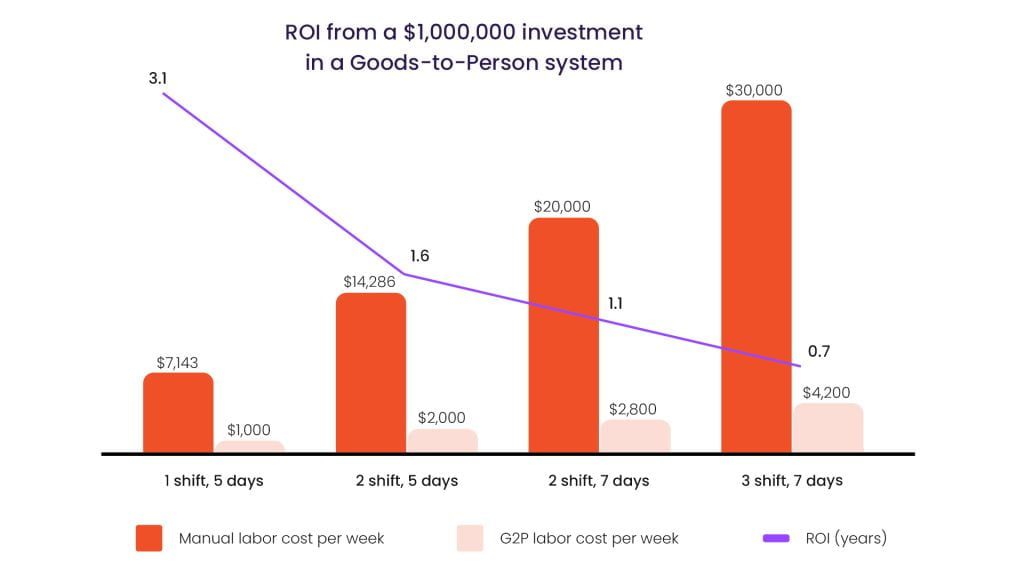

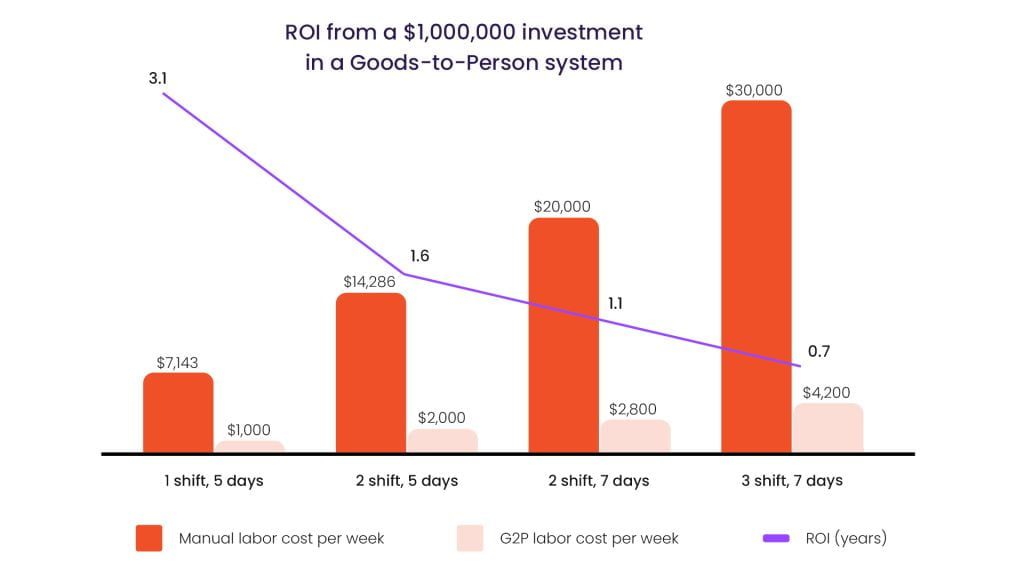

The single biggest driver of ROI is the number of labor shifts you run per day. The cost of automation is constant regardless of usage, but the cost savings you realize depends on how many labor-hours you save.

More shifts equals to greater cost savings and a higher utilization of the automation.

For example, a one-shift operation running 5 days a week would achieve ROI in 3.1 years, compared to just 0.7 years for a 24/7 operation.

In many cases, companies leverage automation to add shifts without extensive hiring. For example, US ecommerce retailer The Feed expanded from two to three shifts per day by reducing labor needs per shift from 35 pickers to just 2, thanks to Brightpick robots. Hiring 4 pickers for a night shift is much easier than hiring 35!

2. Labour cost: are you calculating them right?

Labor reduction is the biggest benefit of automation, so your hourly labor cost will have a big impact on ROI.

When it comes to calculating the cost of labor, hourly wages are just one part of the equation. Factors such as benefits, paid leave, and sick leave can substantially impact actual labor costs. In the US, benefits and paid leave add up to an additional 43% of hourly labor cost, and that’s excluding expenses for hiring, training, and supervising employees.

Considering all ancillary cost savings associated with labor reduction is crucial for accurately assessing the ROI from automation.

Companies that do not account for all related labor costs risk underestimating the ROI from automation, making it harder to build a compelling business case.

3. Higher levels of automation yield better long-term ROI.

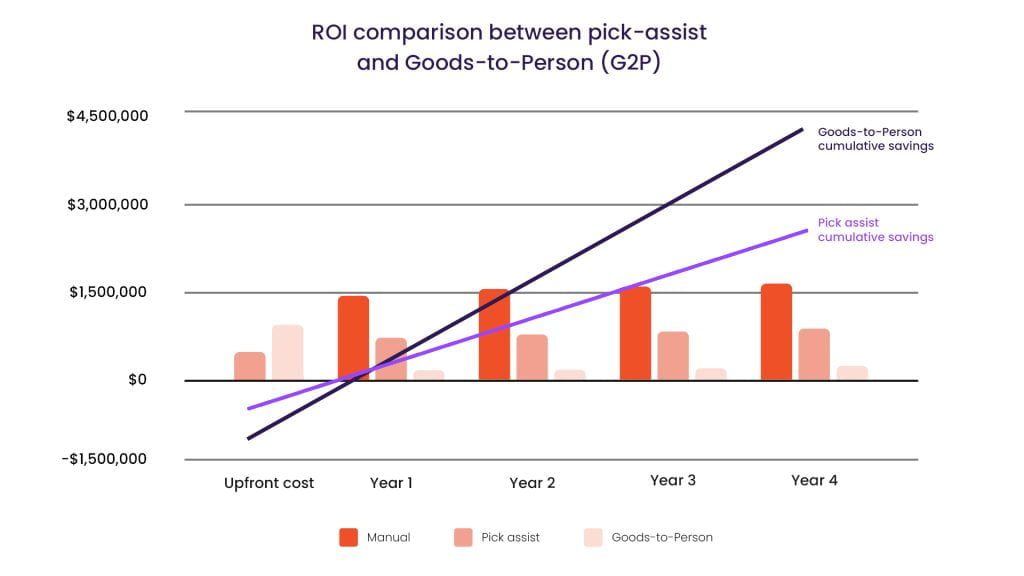

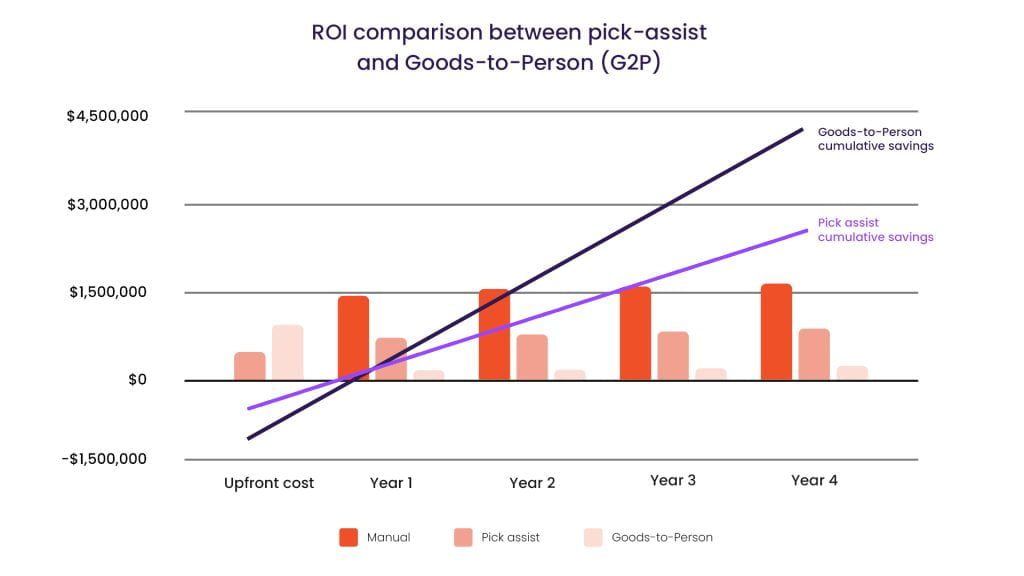

Different types of automation yield varying levels of labor savings. While more advanced solutions may be more expensive, the higher labor savings they provide can result in a superior ROI.

For example, pick-assist cobot solutions are relatively easy and low-cost to install, but they offer limited labor savings compared to more sophisticated Goods-to-Person systems. Even though the pick assist solution may have a shorter payback period, investing more in a Goods-to-Person system can be the better choice because it will generate superior long-term cost savings (especially as inflation increases labor costs).

While more sophisticated automation systems require a higher upfront investment, they will yield higher cost savings and generate a superior ROI over time.

4. Size of operation

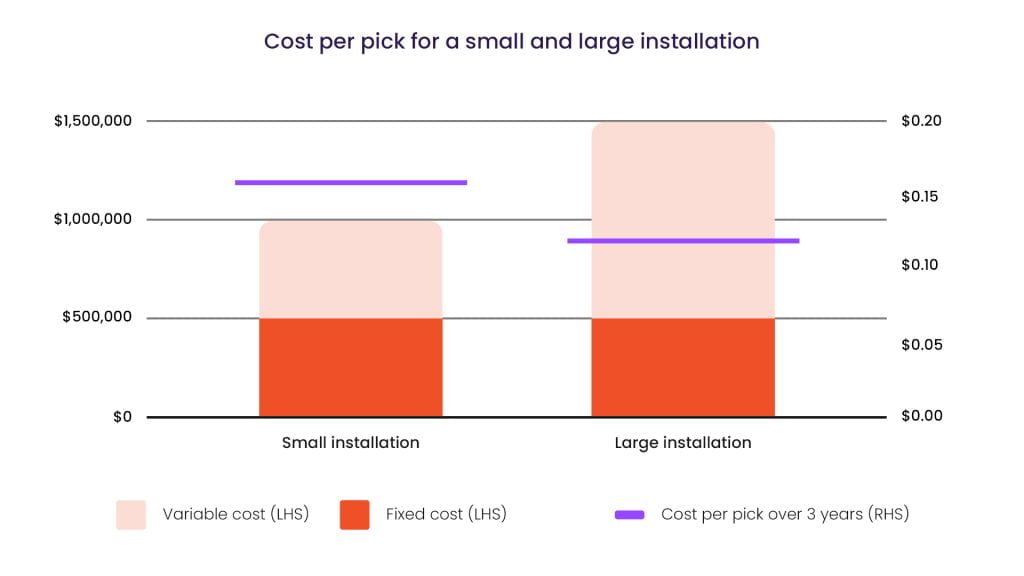

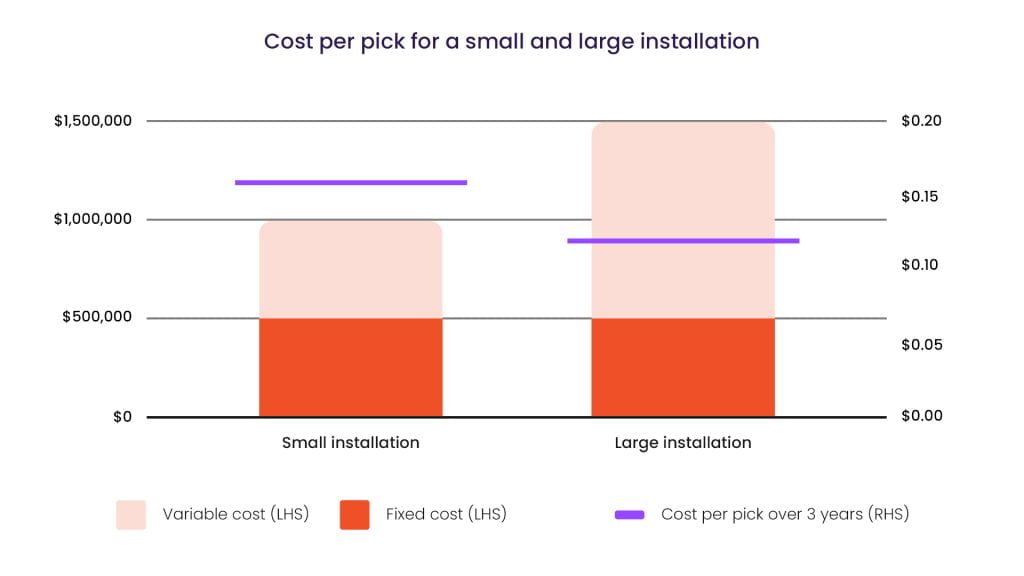

When purchasing automation, the size of the operation can significantly impact ROI and cost per pick.

That’s because installation and support costs are typically fixed, regardless of the installation size. By spreading these costs over a larger number of robots and picks, you can achieve a lower cost per pick and higher ROI.

Strategically purchasing automation for larger sites will result in lower cost per pick and superior ROI.

For example, a solution delivering double the throughput could only cost 50% more, resulting in a 25% reduction in cost per pick.

5. Future growth

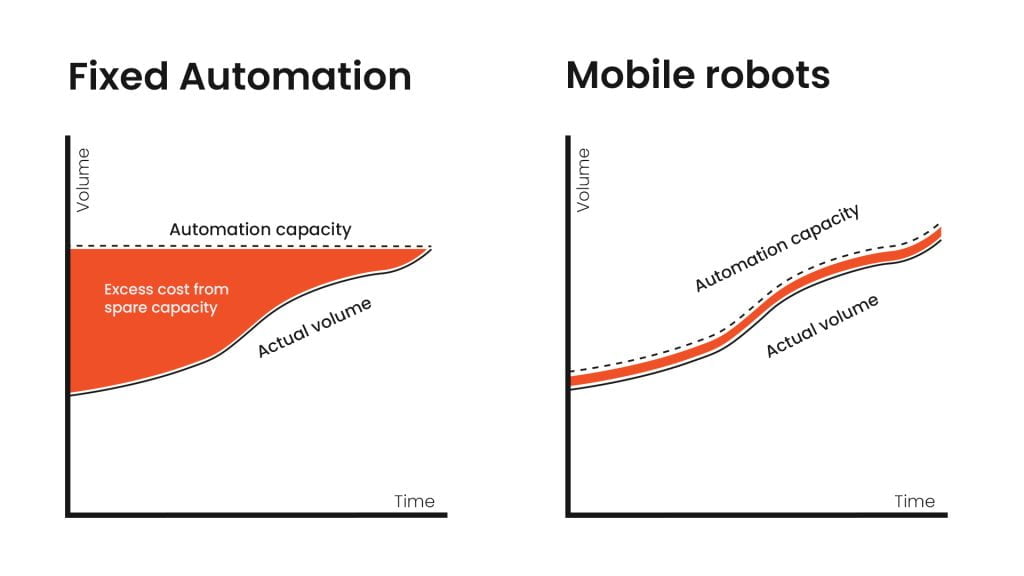

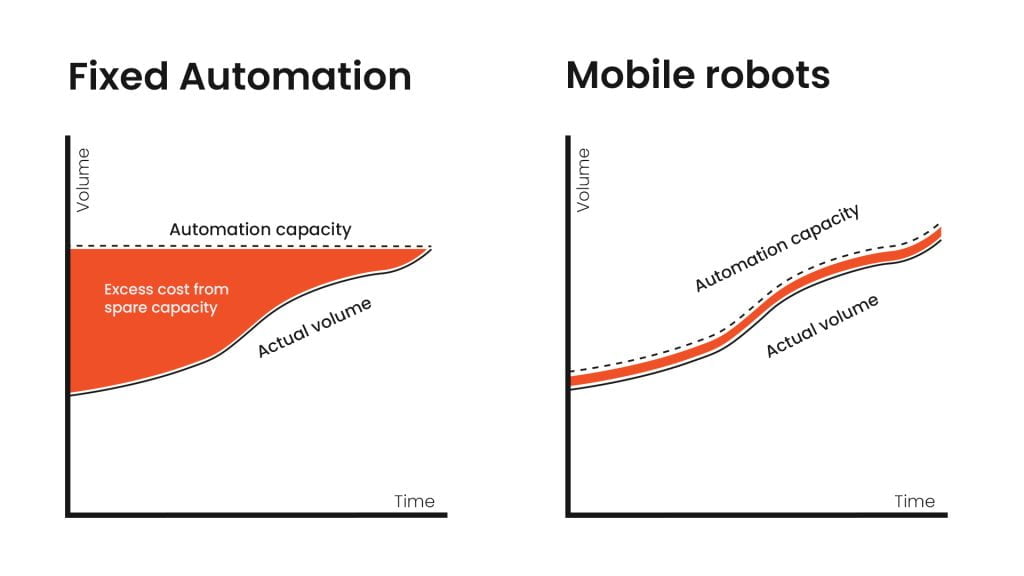

Many companies invest in automation to scale without the need to add warehouse labor or footprint. However, not all automation solutions offer the same scalability.

Fixed automation often forces companies to plan far in advance and invest with a 3-5 year time horizon, leading to higher upfront costs and potential system underutilization in the short-term.

By contrast, flexible solutions like mobile robots allow companies to scale their automation throughput gradually, which reduces upfront costs and enhances ROI.

Investing in scalable automation can improve ROI by minimizing upfront costs and preventing idle capacity.

European cycling e-shop MTBIKER, anticipating strong growth, faced a choice between a cube-based system and Brightpick. The cube-based system required building the solution for their needs three years in advance, resulting in a 50% higher cost. By contrast, Brightpick’s system met their current throughput needs and minimized upfront costs because it allowed them to easily scale each year on demand.

Ready to embrace the future of AI? Brightpick offers an easy path to fully automate your order fulfillment using AI robots. Reach out to learn how we can optimize your operations.

Get started with Brightpick