Order picking

Brightpick Autopicker

Eliminate picking errors, reduce fulfillment costs and ship customer orders faster

Easy-to-install mobile robot solution that fully automates order picking and replenishment

Brightpick Autopicker

Order picking reimagined

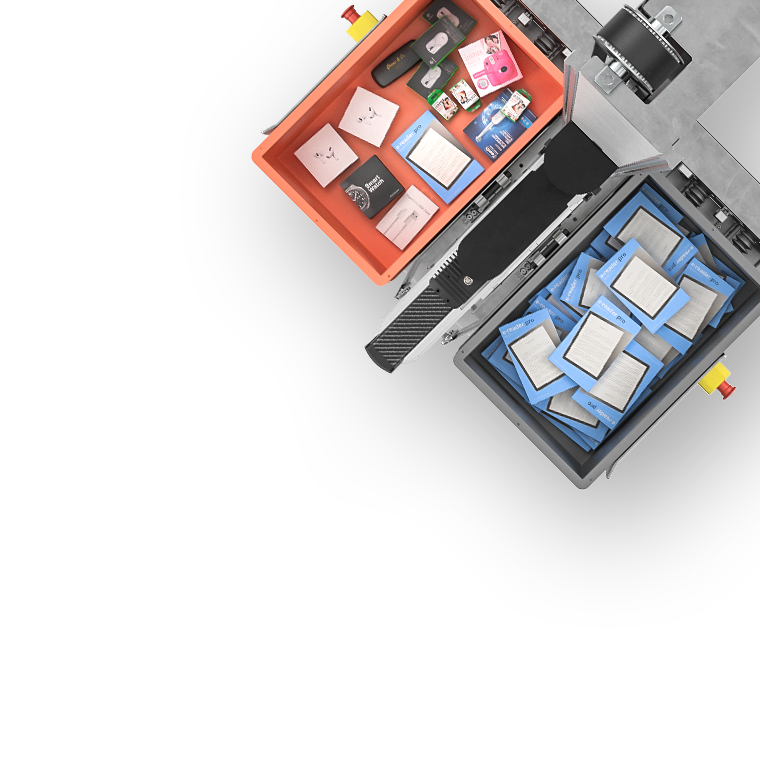

The award-winning Brightpick Autopicker is the only mobile robot in the world that robotically picks and consolidates orders directly in the warehouse aisles, like a human with a cart.

The robot uses a patented two-tote design to retrieve storage totes from shelving and robotically pick items into an adjacent order tote.

Features

INSTALLATION

Build it like Lego

Brightpick Autopickers work with standard shelving and totes – like the ones you find in your local hardware store.

This enables fast deployment and easy integration with any warehouse environment, including existing facilities and mezzanines.

There are no special flooring, fencing or fire safety requirements. Our robots navigate using LiDARs and do not need QR codes or other guidance systems on the floor.

Robotic picking

Maximize efficiency with AI

In-aisle robotic picking eliminates human picking errors, maximizes labor efficiency and cuts picking times in half.

Brightpick Autopicker uses AI to reliably pick ambient and chilled groceries, pharmaceuticals, medical devices, packaged goods, cosmetics, electronics, polybagged apparel and more. Its advanced AI algorithms have been trained on more than a billion picks to date and use machine learning to improve with each pick.

Goods-to-person picking

Never miss a pick

All Brightpick Autopickers come with Goods-to-Person (G2P) capabilities for heavy or complex items, and autonomously find the nearest human picking station to complete a pick if needed.

Our highest-throughput G2P configuration achieves a throughput of 600 tote presentations per hour with a single human picker.

For companies that only need Goods-to-Person picking, Brightpick offers robots without the robotic picking arm.

Brightpick Giraffe

Optimize storage density

Our Giraffe robots can reach as high as 20 feet / 6 meters, allowing you to maximize your warehouse storage density.

Giraffe is designed to work alongside Autopicker. It retrieves storage totes from upper-level shelf locations and delivers them to lower levels, where an Autopicker can access them for picking.

This innovative system maximizes both density and throughput by storing slower-moving items on upper levels (accessible to Giraffes) and fast-moving products within easy reach of Autopickers on lower levels.

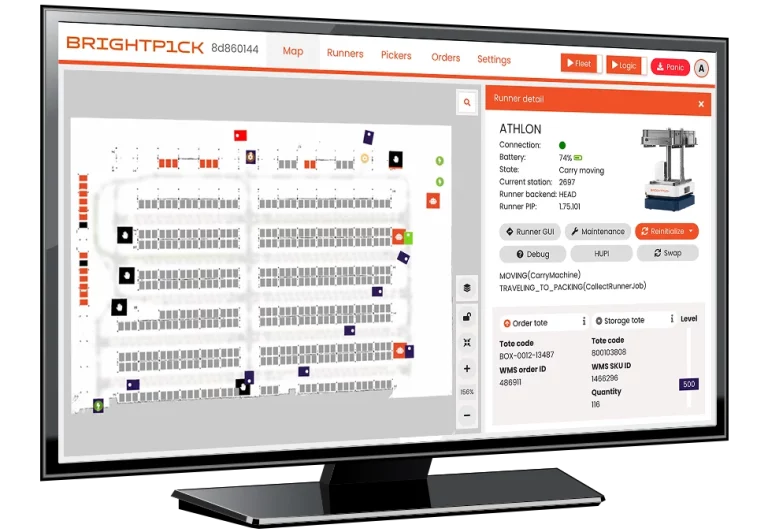

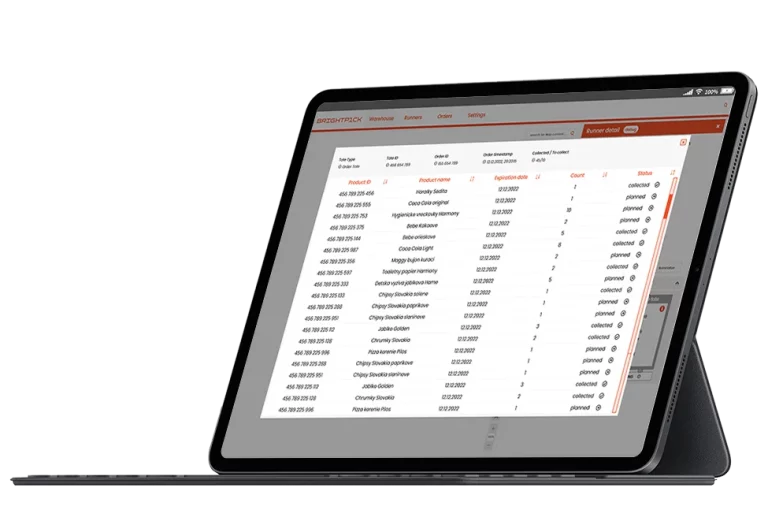

SOFTWARE

The brain that powers everything

Our Brightpick Intuition software seamlessly orchestrates the entire robot fleet and fulfillment process, ensuring maximum efficiency and throughput.

From smart order picking strategies to real-time path planning and inventory optimization, our software intelligently manages every aspect of your operation.

Learn more

ANALYTICS

Your very own digital warehouse

Brightpick Intuition integrates seamlessly with your WMS or ERP system using standard APIs.

The software serves as a digital twin of your warehouse and provides real-time monitoring of all robots and workflows via an intuitive dashboard, ensuring reliable and scalable automation for your business.

Industries

Automate your order fulfillment to reduce labor, cut costs and increase storage density.

Ecommerce

Streamline your order fulfillment, ship orders faster and improve customer satisfaction.

3PL

Win and retain more customers by improving margins and offering superior pricing models.

E-grocery

Improve profitability and offer customers better prices by reducing your fulfillment costs.

Medical

Enhance order accuracy, reduce labor costs, and effortlessly meet regulatory requirements