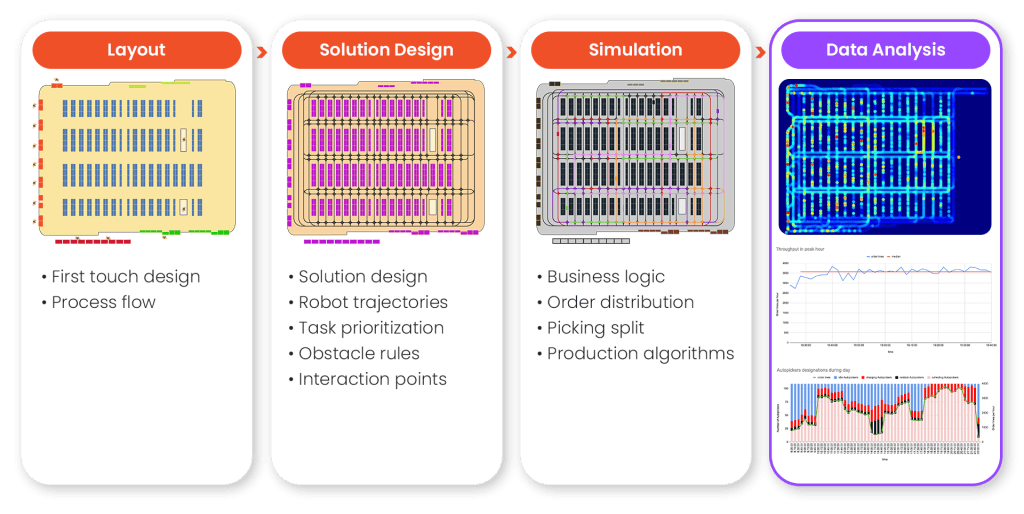

How we simulate our robotic solution before installation

Simulating the solution design before installation reduces risk of inefficiencies and performance variations

The best way to ensure a robotic solution performs as expected is to simulate it before installation. Not just theoretically, but in a way that reflects your actual warehouse and order structure.

At Brightpick, we go beyond rough estimates or static models. Our team of trained engineers build a digital twin of your operation, running high-precision simulations using real production data. This gives you a full-scale, transparent, data-driven view of how our solution will perform in your facility, including layout efficiency, maximum and average daily throughput, and labor needs. This data also allows us to make a robust calculation of the ROI that you will achieve with Brightpick.

What makes our simulations different

We build our simulations based on data from our existing deployments and using the same Brightpick Intuition software that orchestrates our real-world robotic fleet. This ensures that what happens in simulation accurately reflects real robot behavior, including robot path planning, obstacle handling, traffic logic, and dynamic slotting. Our simulations consistently match real-world performance after deployment.

Each simulation evaluates multiple design iterations, testing different solution layouts and picking strategies. We don’t just simulate one design, we optimize the best one for throughput, space, and labor savings.

What you get from the simulation

- A multi-hour 2D simulation of robots operating in your digital warehouse.

- A detailed performance report including:

- Order throughput across average and peak periods

- Robot utilization and charging behavior

- Times to fulfill each order

- Labor requirements by the hour

- Order throughput across average and peak periods

- A visual heatmap showing robot traffic across aisles, restock areas, and picking zones

- Clear data demonstrating how the solution meets your space constraints, labor goals, and throughput targets

Benefits of simulation

- Validates scalability and allows planning for future performance enhancements, for example by adding additional robots or introducing new features such as lights-out overnight picking and buffering

- Provides a realistic preview of how the Brightpick solution will perform based on your actual order structure and production logic

- Outputs reliable and verifiable performance metrics such as throughput, fulfillment time, and robot utilization

- Enables testing of multiple layout and logic configurations to optimize footprint and performance

- Minimizes risk of underperformance or system mismatch before any physical installation

What we need to simulate your operation

To build a high-precision simulation tailored to your warehouse, we start with:

- Total daily orders

- Hourly order volumes

- Order structure (picks, order lines)

- Total number of SKUs

- Inventory days on hand

- Operating hours and labor shift structure

- Warehouse layout

From there, we iteratively refine the simulation based on real order data, shared priorities, and final solution design.

Summary

Investing in warehouse robotics shouldn’t feel like a leap of faith. Our simulations offer more than just reassurance. They deliver clear, measurable insights into how the solution will perform in your operation and ensure a smooth and successful implementation.

About Brightpick

Brightpick is a leader in AI-powered robotic solutions for warehouses. The company’s multi-purpose AI robots enable warehouses of any size to fully automate order picking, buffering, consolidation, dispatch, and stock replenishment. The award-winning Brightpick solution takes just weeks to deploy and allows companies to keep their fulfillment labor to a minimum. With offices in the US and Europe, Brightpick has more than 250 employees and hundreds of AI robots deployed with customers