Solution

Fully automated order fulfillment

Transform your warehouse with AI robots that think, move, and work like humans

Cut costs, eliminate human errors, and boost throughput and storage density

Brightpick Autopicker

The perfect warehouse worker

Autopicker is a multi-purpose robot built to automate a wide range of warehouse workflows, from picking and replenishment to sortation and buffering. It moves seamlessly between tasks and workstations, working like a human – but faster, more consistent, and without breaks.

And it’s ready to start work immediately, from just $1,990/month.

Giraffe and Retriever

Purpose-built assistants

Autopicker is supported by other Brightpick robots designed for specific workflows – like Giraffe, which extends vertical storage up to 19 feet (5.8 meters), and Retriever, optimized for pure Goods-to-Person operations and post-pick order sortation.

FEATURES

End-to-end automated fulfillment

Picking workflows

All your picking needs in one solution

Autopicker handles all types of picking, allowing you to store your entire inventory in one system – regardless of SKU weight, size, or velocity.

Robotic Picking

- Autopickers robotically pick items directly inside the storage aisles

- Speeds up order picking and maximizes labor savings

Goods-to-Person Picking

- Robots bring products to a picking station, where an operator completes the pick

- Used for complex / heavy items, batch picks, and as a fallback to robotic picking

- 500+ order lines per hour per station

Fast Lane

- Operators pick items directly from pallets or cases and place them in the robot’s order tote

- Used for fast-moving SKUs (A/A+ movers)

- Eliminates need to decant products into storage totes

lights out

24/7 fulfillment, even in the dark

Autopicker works around the clock – even when your team isn’t there. The robots can autonomously pick and buffer orders overnight, so they’re ready to be packed and shipped the moment the morning shift starts.

This allows you to extend your operations into night shifts and weekends – shipping more orders without adding labor or cost.

Brightpick robots can even run without light. Thanks to advanced 3D vision and AI, they operate flawlessly in complete darkness, turning your warehouse into a truly lights-out operation.

Integration

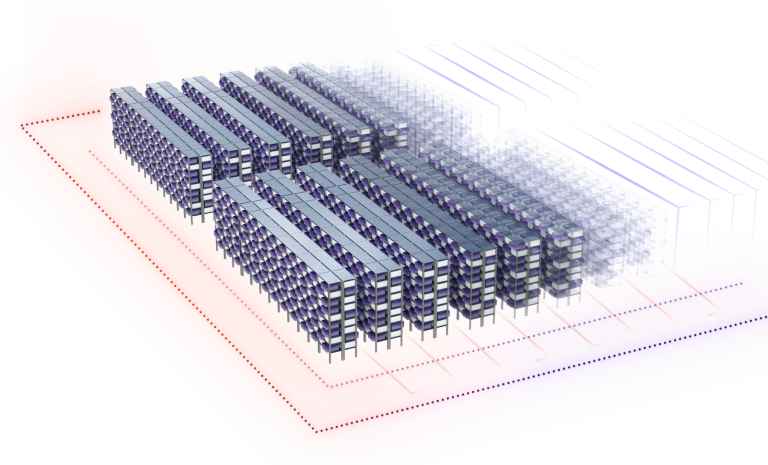

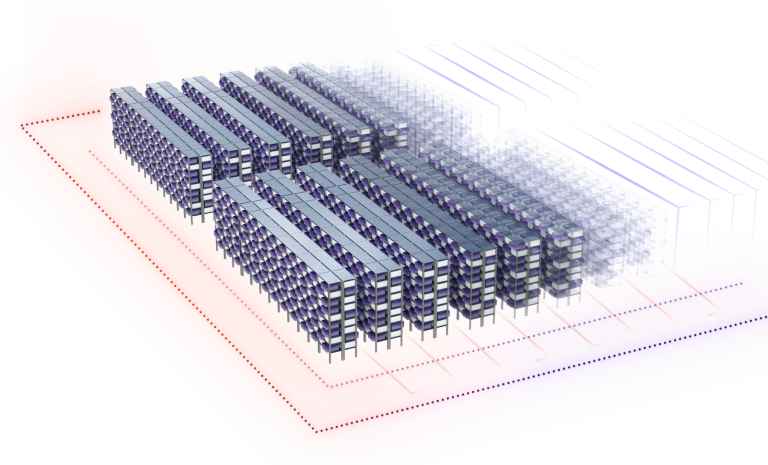

Build it like LEGO

On-site installation takes just 3-4 weeks. Autopickers work with standard shelving, which can be easily assembled, reconfigured or relocated – giving you maximum flexibility as your operations grow or change.

The system is compatible with virtually any warehouse environment, including existing facilities and mezzanines. There’s no need for specialized flooring, fencing, or fire safety modifications.*

The robots use SLAM and AI-based navigation, without the need for QR codes, markers, or fixed guidance infrastructure on the floor.

* up to 10 feet (3 meters) in shelving height. Taller installations may be subject to local fire safety regulation and floor flatness requirements.

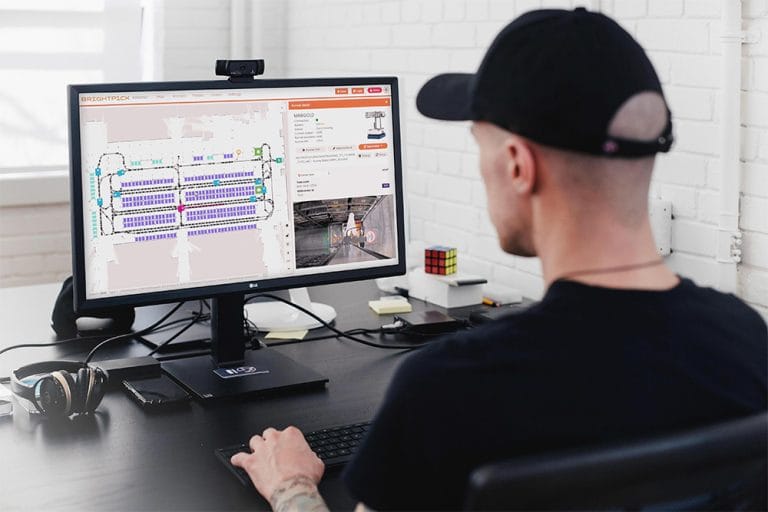

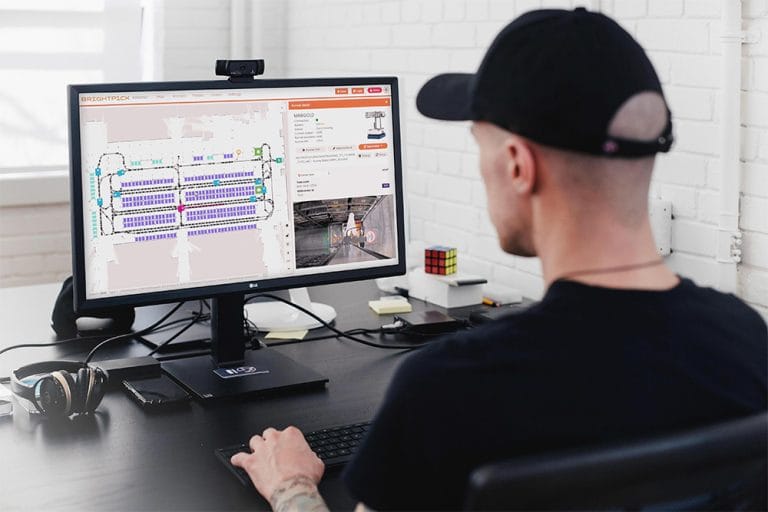

Integration

Plug-and-play with your existing operations

Brightpick is designed to plug into your operation with minimal disruption. Our robots integrate easily with existing infrastructure – such as conveyors, mezzanines, and packing stations – delivering totes and orders precisely when and where you need them.

Our Intuition software acts as a smart control layer between your WMS and the fulfillment process. It receives order and stock replenishment data, orchestrates all fulfillment workflows, and tracks every inventory movement in real time. Integration is handled via standard APIs, requiring minimal effort from your IT team.

Reliability

Always in control

Reliability is mission-critical for any fulfillment center. That’s why Brightpick is engineered from the ground-up to deliver 100% uptime, with no single point of failure and built-in reduncancies throughout the system.

All robots are fully interchangeable, meaning if one goes down, the rest of the fleet keeps running without disruption. Every installation includes spare capacity to maintain performance even during routine maintenance or servicing.

The system requires no safety fencing and is fully accessible to trained technicians at all times. And in the rare event of a major disruption, such as a power outage, your inventory remains fully accessible, with no risk of it being trapped inside a closed system.

Support

Your reliable service partner

Every Brightpick installation includes 24/7 remote support as standard. Our remote technicians proactively monitor your system and can step in to resolve issues in real time.

Our standard support package includes all necessary repairs, with optional preventative maintenance available for added peace of mind. Each installation is stocked with its own spare parts inventory, and our distribution centers in Texas and Slovakia enable parts delivery within 24 hours across the U.S. and Europe.

Pricing models

Available for purchase or hire

Brightpick offers flexible commercial options to fit your business needs. Choose between a regular purchase or a subscription model for lower upfront costs and faster ROI.

- Monthly subscription payment for robots and software

- Only totes and racking as CapEx

- Implementation fee of $1000 per robot (minimum of $70k)

- ROI in 3-6 months

- Guaranteed performance, throughput, and uptime

- Optional on-site support

- Remote support 24/7/365

- All maintenance and software upgrades included

- 3-year contract term (additional discount for longer terms)

- Minimum 10 robots per installation

- One-time payment for all hardware and implementation

- You own all hardware and software

- Low monthly fee for maintenance and support

- ROI in 1-2 years

- Guaranteed performance and throughput

- Optional on-site support and preventative maintenance

- Remote support 24/7/365

- Minimum 10 robots per installation

Solution

Learn more about Brightpick