PERFORMANCE

Maximum labor savings

Brightpick robots don’t just move goods from point A to B. They also robotically pick, consolidate and replenish, delivering maximum labor and cost savings for your operation.

| ||

|---|---|---|

| Automated putaway | ||

| Robotic picking | ||

| Order buffer | ||

| Automated order consolidation | ||

| Automated storage and retrieval | Partial | |

| Throughput | High | Moderate (depends on human pickers) |

Return oN investment

Higher ROI and cost savings

By automating costly manual tasks, increasing storage density and eliminating human picking errors, Brightpick helps you achieve a faster return on investment and higher cost savings.

| ||

|---|---|---|

| Labor reduction | High | Low |

| Cost savings | High | Low (Human dependencies) |

| Storage density | 3x increase | No improvement |

| Picking accuracy | Extremely high (robotic picking) | Depends on human accuracy |

Pricing

Flexible pricing models

Brightpick is available through Robots-as-a-Service (RaaS), starting from just $1,990 per robot / per month.

RaaS transforms warehouse automation from a large upfront capital investment into a manageable monthly operating cost, which reduces financial risk, simplifies budgeting, and delivers immediate ROI.

Alternatively, the Brightpick solution is also available through a standard CapEx purchase.

Learn moreinstallation

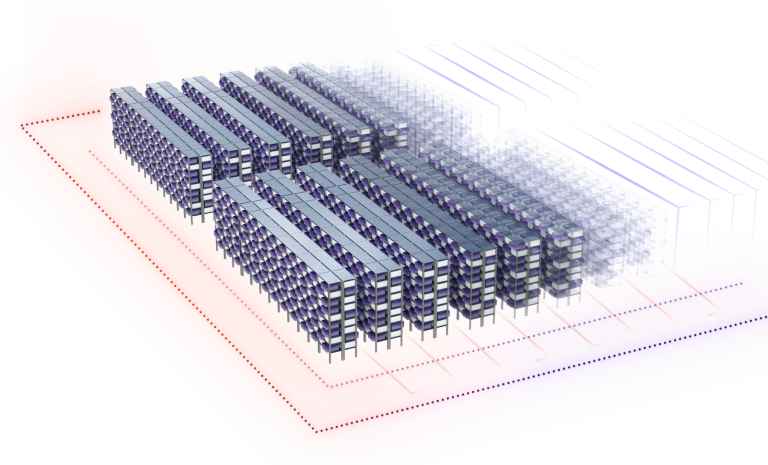

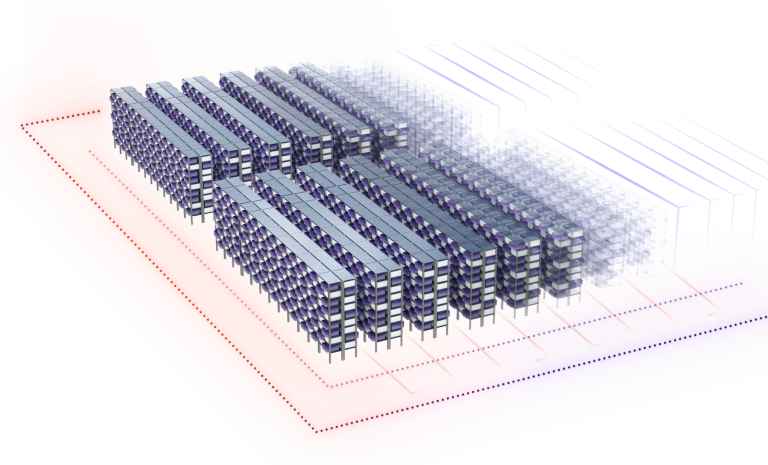

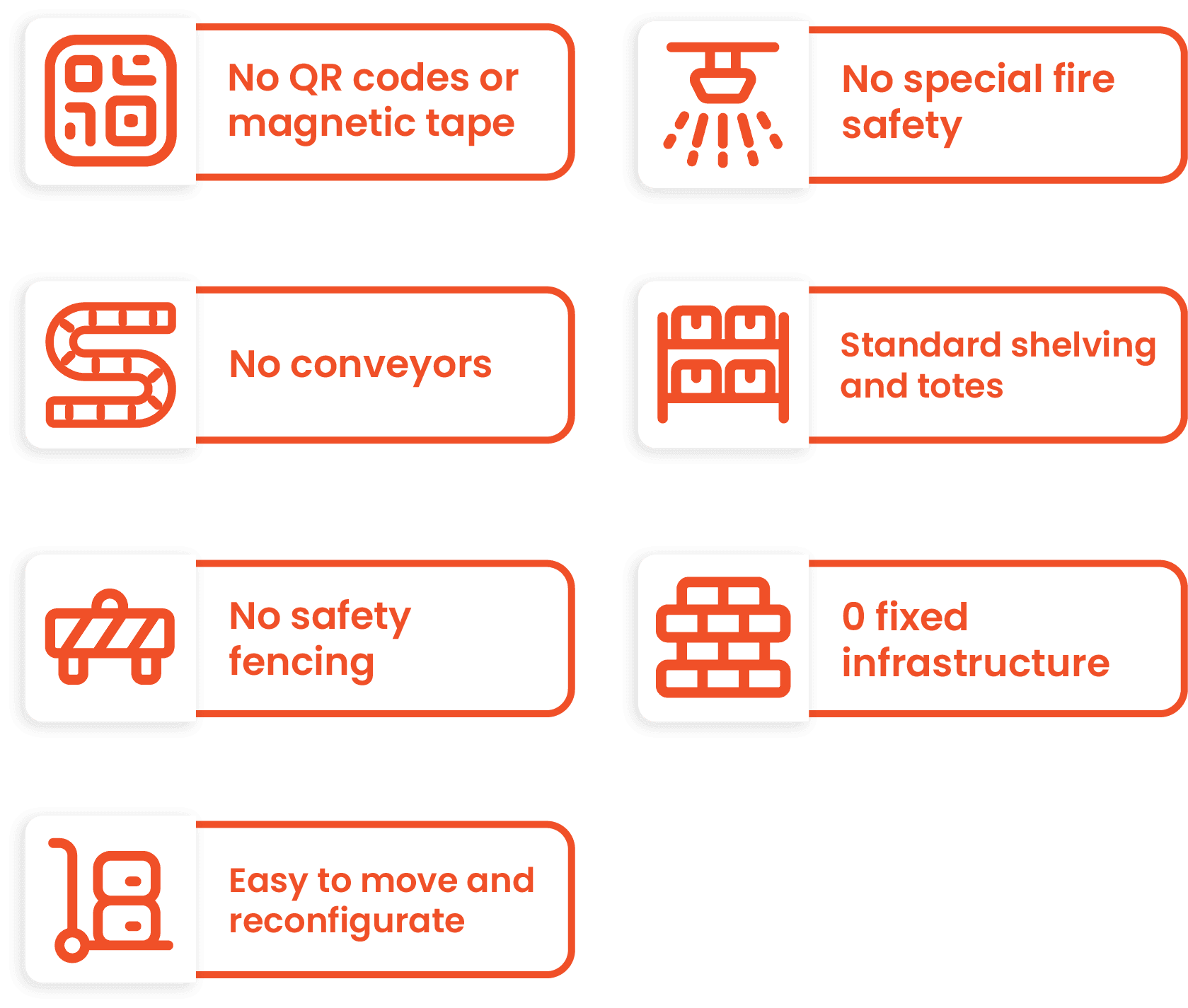

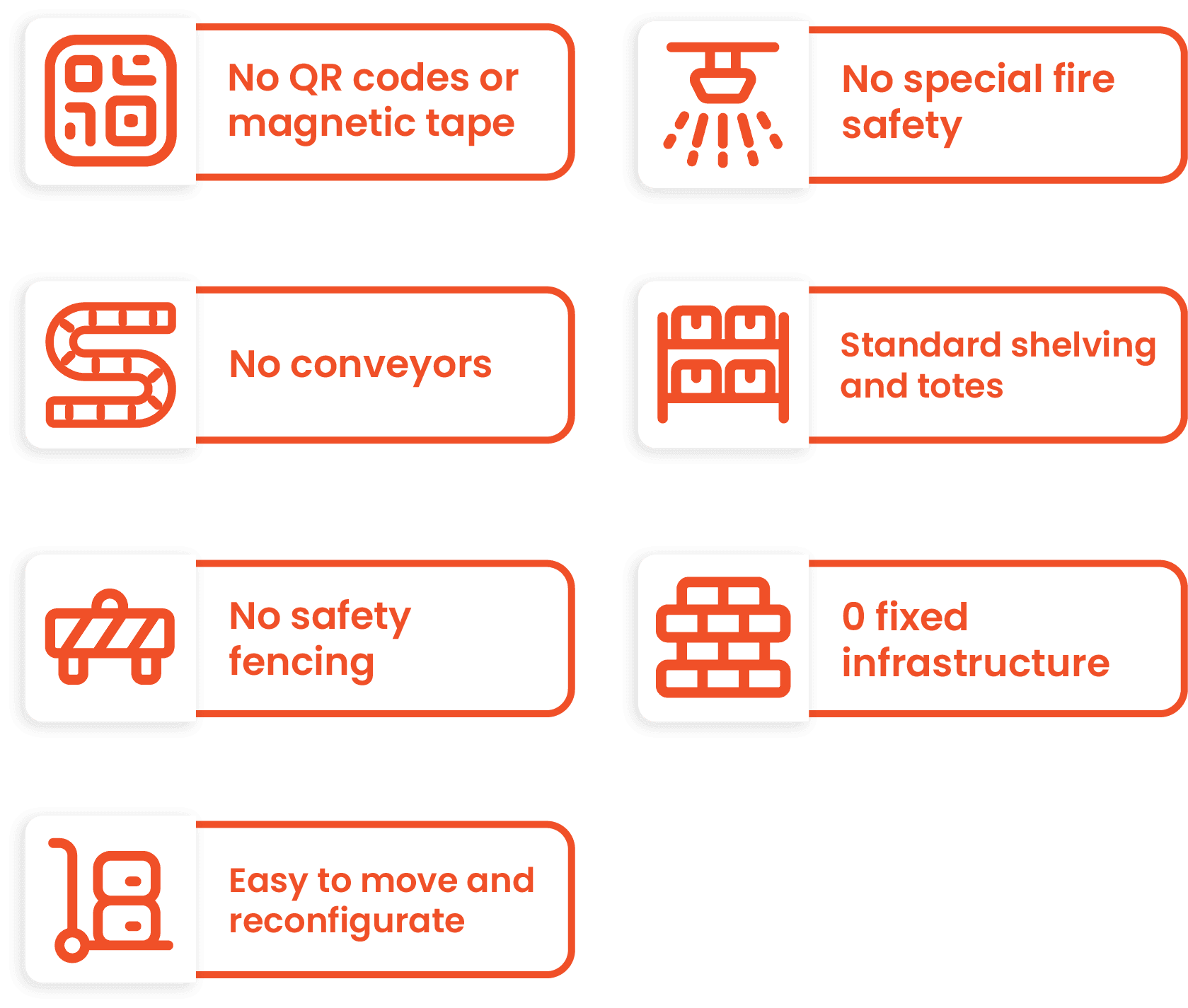

Easy to install and scale

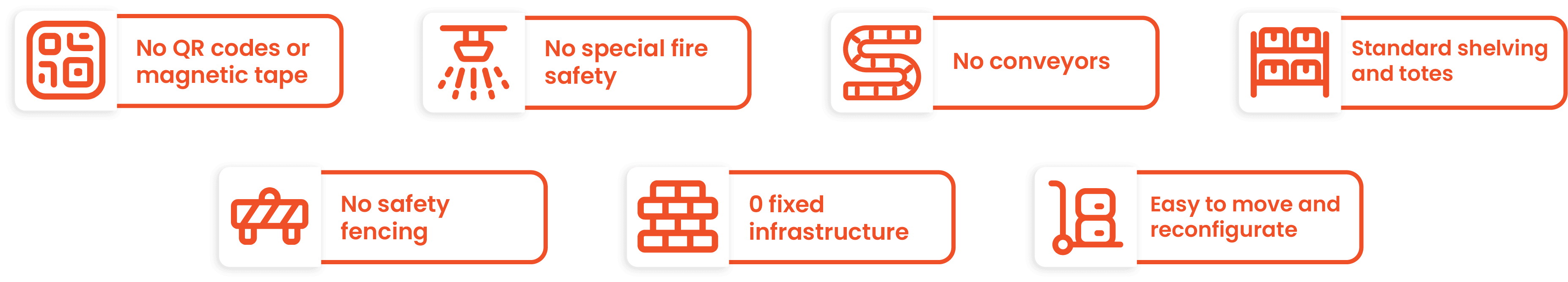

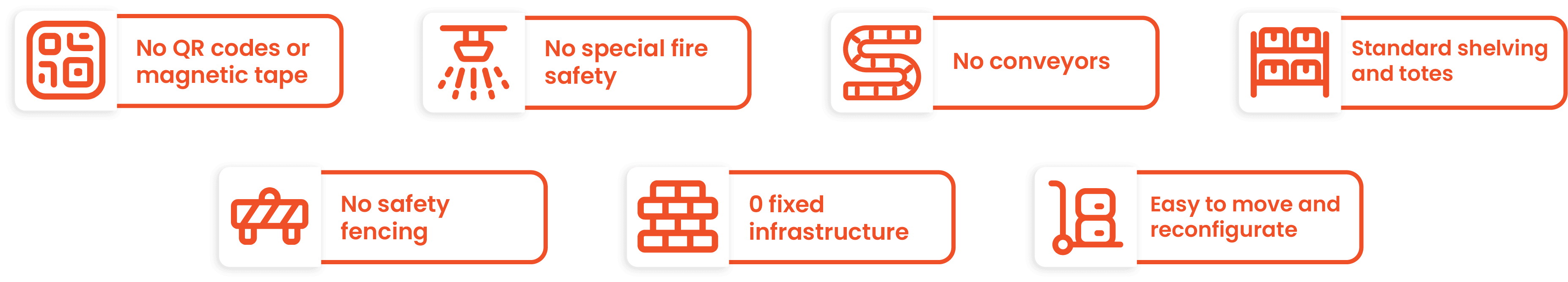

Brightpick robots work with standard shelving and totes and require no fixed infrastructure. This enables fast deployment and easy integration with any warehouse environment, including existing warehouses and mezzanines.

What our customers say

Virtual demo

Watch our virtual demo of Brightpick Autopicker

Get Brightpick pricing & ROI

Whitepaper includes:

- Suitability (is Brightpick the right solution for you?)

- Pricing (transparent cost breakdown)

- ROI and savings (analysis of financial benefits)

- Solution design (detailed breakdown of the Brightpick system)

- Implementation timeline (step-by-step process to go live)

Frequently Asked Questions

-

What is the main difference between Brightpick and Locus Robotics?

Locus Robotics is an assisted picking solution, where autonomous mobile robots (AMRs) guide human operators to each pick location within the warehouse. Brightpick takes a different approach, using robots that can autonomously pick items from storage, with human operators stepping in only for exceptions at dedicated pick stations.

-

Is Brightpick a good alternative to Locus?

Brightpick is suited for businesses that prioritize labor and cost savings, higher throughput, storage density, and scalability. Locus Robotics is suited for businesses that value maximum flexibility and prefer to keep human operators central to the picking process, though this typically results in lower labor savings.

-

Does Brightpick or Locus Robotics provide higher labor savings?

Brightpick can deliver higher labor savings because its robots are able to autonomously pick items from storage, reducing the need for human operators inside the storage area.

Assisted picking solutions like Locus still rely on people to pick and handle products, with collaborative robots (CoBots) focused on guiding operators and transporting items. Actual results depend on SKU mix, order profiles, and workflows.

-

Can Brightpick eliminate manual picking entirely?

It depends on the types of SKUs being handled. In some applications, such as pharmaceuticals, Brightpick Autopickers can pick 100% of SKUs and fully automate the process. In other cases, such as general merchandise, a small number of human pickers may still be required at Goods-to-Person stations.

-

How do Brightpick and Locus handle fast-moving A-class SKUs?

Both Brightpick and Locus can automate fast-moving products. Brightpick offers a Fast Lane feature, where robots pull up to dedicated pallet or picking positions so human operators can retrieve items directly from pallets or cases and place them onto the robots.

-

What tasks does Brightpick automate compared to Locus?

Like Locus, Brightpick robots autonomously transport orders and inventory around the warehouse. In addition, Brightpick robots fully automate picking, order buffering, consolidation, replenishment, and putaway.

-

How does picking accuracy differ between Locus and Brightpick?

Locus Robotics improves picking accuracy by guiding human operators to the correct location and displaying the item to pick on a screen, though human errors can still occur. Brightpick eliminates human error entirely by automating the picking process using AI and 3D vision.

-

Which solution provides more scalability – Brightpick or Locus?

Both solutions are scalable, but in different ways. With Locus, adding more assisted picking AMRs is straightforward, but additional labor is required to increase throughput. Brightpick can be scaled by adding more robots and extending the storage area with standard shelving, without a proportional increase in labor.

-

Which solution is easier to install?

Both Brightpick and Locus are relatively easy to install, operate safely around people, don’t require fixed navigation markers, and require minimal supporting infrastructure. Locus typically works with a company’s existing shelving or pallet storage. Brightpick requires the installation of simple shelving and transferring inventory into totes.

-

How do picking rates compare between Brightpick and Locus?

Brightpick and Locus offer similar throughput per robot. The difference is in labor requirements: Locus typically requires one human for every 3–4 robots, while Brightpick can average one human for every 10–20 robots. Actual results depend on SKU mix, order profiles, and workflows.

-

How do I determine if Brightpick or Locus is better for my warehouse?

It depends on your priorities. Brightpick is suited for companies that want to maximize labor and cost savings through end-to-end robotic automation. Locus is suited for companies that want to boost human productivity with minimal process changes. Both solutions are flexible and relatively easy to install.