How does Brightpick compare to AutoStore?

Brightpick delivers higher labor savings and throughput while being easier to install, maintain and scale.

PERFORMANCE

Higher labor savings and throughput

Brightpick automates more fulfillment processes and delivers high throughput regardless of order profile.

| Automated storage and retrieval | ||

| Automated putaway | ||

| Robotic picking | ||

| Order buffer | ||

| Automated order consolidation | ||

| Throughput | High | Medium (depends on order profile) |

| Max height | ~6 meters (20 feet) | ~6 meters (20 feet) |

PRACTICALITY

Easier to install and maintain

Our robots can be deployed in weeks and don’t require any fixed infrastructure or strict floor flatness. The Brightpick solution can be easily scaled by simply adding additional shelving and robots.

| Deployment Time | Weeks (no fixed infrastructure) | Months (requires extensive infrastructure) |

| Floor flatness requirements | Minimal | Strict |

| Flexibility | High (easy to move and reconfigure) | Very Low (limited to fixed grid) |

| Maintainability | Good (all parts easily accessible) | Poor (may require pausing system) |

| Single point of failure | No | Yes (failure on grid requires pausing system) |

Pricing

Flexible pricing models

Brightpick is available through Robots-as-a-Service (RaaS), starting from just $1,990 per robot / per month.

RaaS transforms warehouse automation from a large upfront capital investment into a manageable monthly operating cost, which reduces financial risk, simplifies budgeting, and delivers immediate ROI.

Alternatively, the Brightpick solution is also available through a standard CapEx purchase.

Learn moreWhat our customers say

Virtual demo

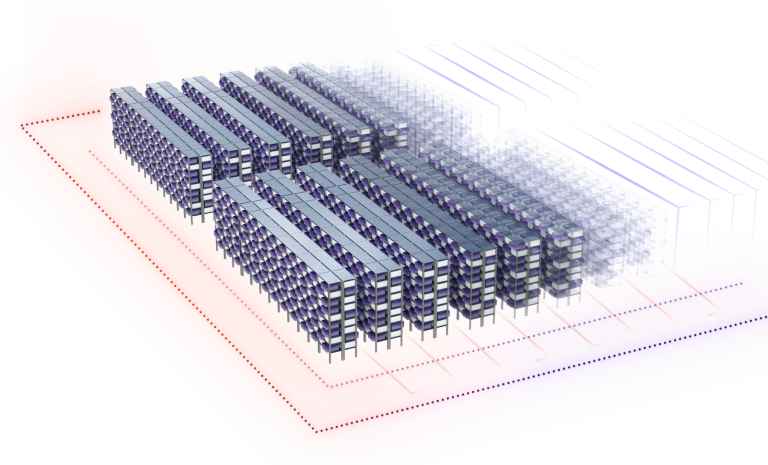

Watch our virtual demo of Brightpick Autopicker

Get Brightpick pricing & ROI

Whitepaper includes:

- Suitability (is Brightpick the right solution for you?)

- Pricing (transparent cost breakdown)

- ROI and savings (analysis of financial benefits)

- Solution design (detailed breakdown of the Brightpick system)

- Implementation timeline (step-by-step process to go live)

Frequently Asked Questions

-

What is the main difference between Brightpick and AutoStore?

AutoStore is a cube storage ASRS in which robots move on top of a grid to retrieve bins and deliver them to picking stations. Unlike AutoStore, Brightpick uses mobile robots that navigate warehouse aisles and work with standard shelving and totes, making the system easier to install and scale.

-

Is Brightpick a good alternative to AutoStore?

Brightpick could be a strong alternative to AutoStore in cases such as: brownfield facilities where heavy retrofits are undesirable, projects requiring rapid installation, operations with a flat volume distribution across SKUs, warehouses with changing inventory profiles, businesses that value flexibility, operations that need easily scalable throughput, and companies targeting maximum labor reduction.

By comparison, AutoStore is well suited for businesses prioritizing storage density with stable inventory and production profiles and limited need for future scaling.

-

How do I know if Brightpick or AutoStore is better for my warehouse?

It depends on priorities. Brightpick is suited for fast-growing companies that value flexibility, quick scalability, and minimal labor. AutoStore is suited for companies that prioritize storage density and have stable, mature operations.

-

How long does it take to install Brightpick compared to AutoStore?

Brightpick can be installed in most warehouses within weeks, with a typical on-site installation time of 2-4 weeks from delivery to go-live. Cube storage installations generally take longer due to more extensive retrofits and construction. Actual timelines depend on site conditions and scope.

-

Can Brightpick scale more easily than AutoStore?

Brightpick does not rely on a fixed grid, so scaling can be as simple as adding robots and shelving. Scaling cube-storage systems typically requires grid extensions, additional ports, and supporting infrastructure such as conveyors.

-

Does Brightpick require major infrastructure changes like AutoStore?

Unlike cube-based systems, Brightpick does not require fixed infrastructure such as grids or conveyors, strict floor flatness, or extensive fire safety modifications.

-

Which system is easier to reconfigure – Brightpick or AutoStore?

Brightpick relies on mobile robots and standard shelving, which makes it easier to reconfigure or relocate. Grid-based ASRS can be expanded, yet are generally harder to change or adapt once installed.

-

Does Brightpick or AutoStore provide higher labor savings?

Cube-storage systems typically rely on Goods-to-Person stations, so human operators are still needed to complete picks. Unlike AutoStore, Brightpick robots can robotically pick items directly in-aisle and use Goods-to-Person stations only when required. This enables higher labor savings and throughput, although actual results depend on SKU and order mix.

-

Does Brightpick offer similar storage density to AutoStore?

Both Brightpick and AutoStore can reach a maximum height of about 20 feet (6 meters). AutoStore achieves higher storage density by eliminating aisles and stacking totes, however that requires digging for totes which can affect throughput in certain cases.

-

How do picking rates compare between Brightpick and AutoStore?

Both systems support different configurations of Goods-to-Person stations, with throughput typically ranging from 100 to over 500 tote presentations per hour. In addition, Brightpick robots can robotically pick items directly in-aisle, providing additional throughput capacity.

-

Which is more reliable, Brightpick or AutoStore?

Both Brightpick and Autostore are highly reliable systems. Brightpick is designed without a single point of failure, since robots operate independently and operators can enter the system without interrupting operations.