Meet Brightpick Intuition, the software brain behind our robots

What would happen if you let dozens of robots roam a warehouse on their own? It wouldn’t take long for chaos to unfold. Our robots are smart, but even they need a central brain that optimizes the entire fleet.

That’s where Brightpick Intuition comes in, our AI software that powers all our robots and acts as the digital brain of your warehouse. Let’s take a closer look at all its advanced capabilities:

1. Smart order fulfillment

Brightpick Intuition orchestrates our entire robot fleet with precision, controlling every movement and fulfillment workflow across your warehouse to maximize throughput and speed.

When new orders arrive from your WMS or ERP, it promptly directs robots to pick and dispatch them, dynamically prioritizing tasks and assigning new jobs based on current needs.

In case a robot is unable to robotically pick an item, Brightpick Intuition automatically directs it to the nearest G2P (Goods-to-Person) stations, ensuring uninterrupted workflows.

From picking orders to restocking inventory, the software ensures that the optimal number of robots focus on high-priority tasks. For larger orders, it automatically splits picks across multiple totes and consolidates them before dispatch. On the other hand, smaller orders are batched together and handled by a single robot.

During quiet periods, robots recharge intelligently to keep the entire fleet ready for peak times.

2. Inventory optimization

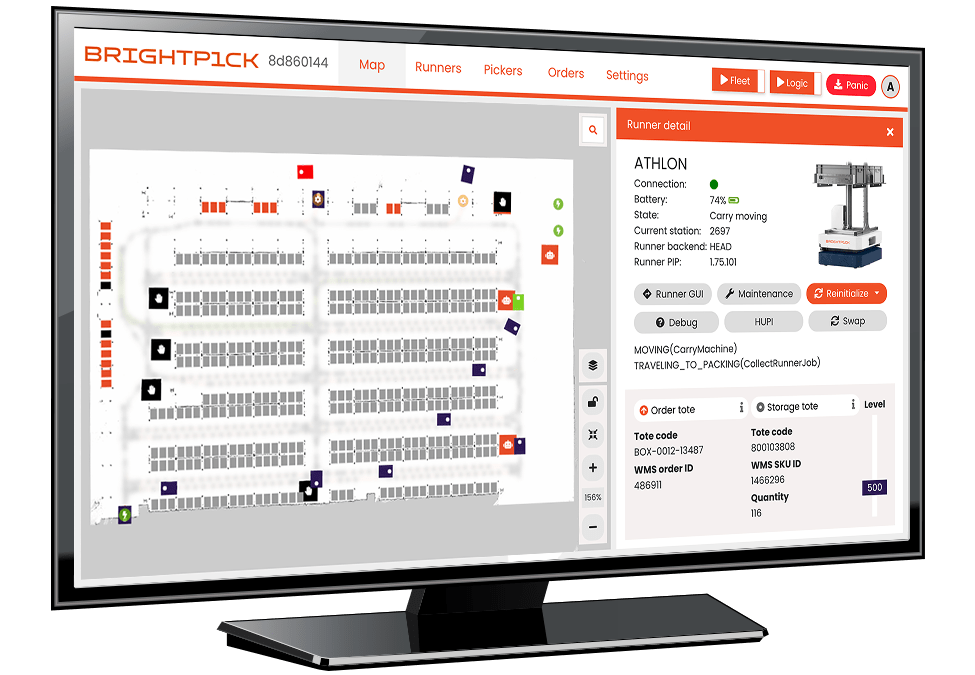

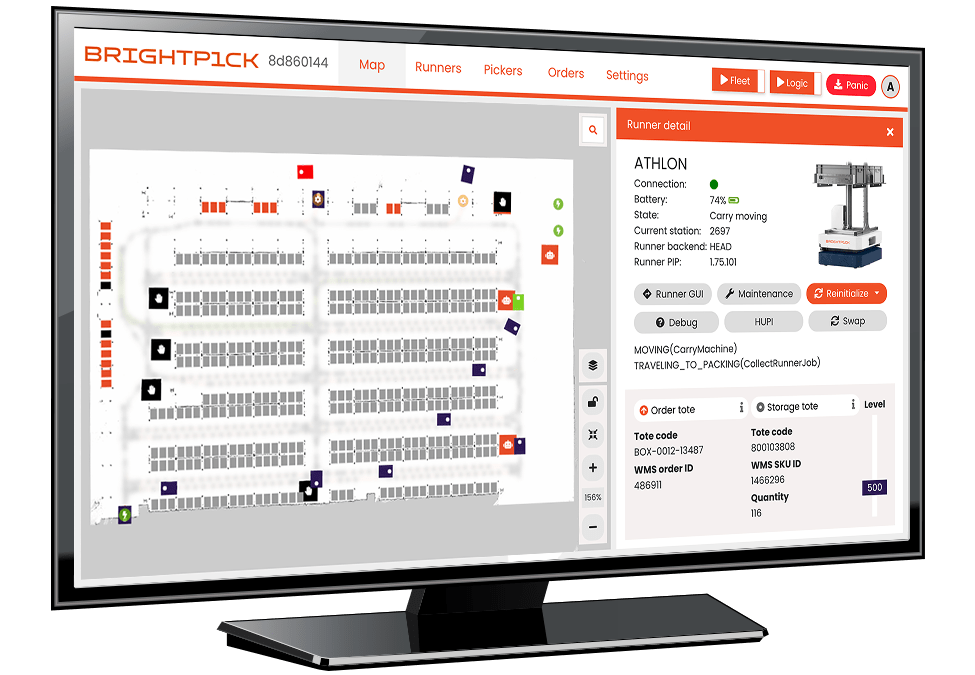

Brightpick Intuition tracks all inventory in real time, allowing you to easily locate every SKU through our intuitive user interface. Our software tracks each SKU and batch independently, making it simple to isolate and recall a specific batch when needed for quality or safety reasons. Inventory can also be recalled quickly for cycle counting, quality control, or returns handling.

Using dynamic slotting, the software optimizes storage by positioning high-demand SKUs closer to packout stations, reducing travel time and maximizing efficiency. You can also implement custom picking strategies – such as First-Expiry-First-Out (FEFO), FIFO, or LIFO – to optimize inventory management. With active weight management, it ensures each robot can safely handle heavy totes, enhancing performance and minimizing errors to keep operations smooth and reliable.

3. Efficient path planning

At the core of Intuition is our AI-powered Time-Space Planning algorithm, which continuously predicts fleet activity and dynamically re-plans robot paths to avoid congestion and maximize throughput.

Each robot’s route is calculated in real time depending on its next task. Brightpick Intuition calculates the most optimal path not only to minimize travel distance, but also to avoid slowing down other robots or creating congestion. Real-time re-planning ensures uninterrupted operations even if something unexpectedly changes while the robot is already traveling. All this ensures Brightpick robots can work efficiently even in the busiest warehouse environments.

4. Real-time performance monitoring

Brightpick Intuition provides comprehensive performance dashboards and metrics, giving you full visibility into your warehouse’s operations. With proactive alerts sent directly to your communication channels, you’re always in the loop and able to immediately resolve any issues.

In addition, operational suggestions such as “Add more totes to XX” or “Running out of inventory in SKU Y” mean you always stay ahead of potential issues. Plus, with 24/7 remote support from Brightpick, you always have a helping hand whenever a challenge arise.

Brightpick Intuition goes beyond basic robotic software functionality. It effectively becomes a digital twin of your warehouse, providing you with real-time oversight and ensuring reliable and consistent operations at all times.

Ready to embrace the future of AI? Brightpick offers an easy path to fully automate your order fulfillment using AI robots. Reach out to learn how we can optimize your operations.

Get started with Brightpick