How AMRs work in real warehouse operations

Autonomous mobile robots are becoming a standard part of modern supply chains. They move, pick, and organize vast numbers of products every day in warehouses around the world.

Yet many people still wonder how these robots actually work in real warehouses. This Q&A breaks it all down.

What types of AMRs exist for order picking?

For order picking, warehouses typically use three main types of Autonomous Mobile Robots (AMRs). Each type automates picking in a different way and delivers a varying levels of labor reduction and throughput.

1. Directed picking AMRs

These robots guide human pickers through the warehouse and carry order totes or cartons. The robot tells the worker what to pick and where, but the human still performs the physical pick. The main benefit is reduced walking and increased productivity for employees with minimal changes to the warehouse.

2. Goods-to-Person robots

G2P systems bring inventory directly to static picking stations. The worker stays in one place while robots deliver the inventory to them. Robots can carry either individual totes or entire shelves and bring them to the picking stations. The goal is to eliminate walking for humans and maximize picking speeds at the station.

3. Mobile manipulators

Mobile manipulators are robots that operate fully autonomously and robotically pick items using vision and AI. They retrieve storage totes, identify the correct products, and pick them directly into their order containers. For items they cannot manipulate autonomously, they typically transport them to the closest human station. This approach delivers the highest labor reduction for item-level picking.

All three types of AMRs reduce picking labor and improve productivity. Directed picking reduces walking, Goods-to-Person eliminates walking entirely, and mobile manipulators automate the entire picking process, from transportation to picking. The right choice depends on your labor costs, order volume, SKU mix, and how far you want to push automation inside your existing warehouse.

Who are AMRs best suited for?

AMRs are best suited for companies that value flexibility, scalability, and cost efficiency. Compared to fixed automation, AMRs typically have lower upfront costs, shorter deployment timelines, and can easily scale as volumes grow.

There is a wide range of AMR solutions, from assisted picking robots that reduce walking to fully autonomous mobile picking robots that handle item-level picking. This makes AMRs a good fit for operations that want to automate step-by-step instead of committing to a single, rigid system.

AMRs work especially well in environments with changing demand, expanding SKU counts, or evolving layouts. They are commonly used by e-commerce, retail, pharma, and 3PL operations where adaptability matters.

On the other hand, AMRs are usually less suitable for facilities with extremely high, stable volumes and highly standardized workflows. In those cases, large fixed systems can sometimes deliver lower cost per unit at full scale. For most operations facing labor pressure and uncertainty, however, AMRs offer a practical and economically sound path to automation.

How do AMRs navigate in warehouses?

AMRs use several navigation methods, each with different levels of flexibility and infrastructure requirements.

The main types are:

SLAM-based navigation (most modern approach)

SLAM, or Simultaneous Localization and Mapping, uses LiDAR sensors, cameras, and wheel odometry to build a live map of the warehouse and localize the robot in real time. This allows robots to operate on standard concrete floors, adapt to layout changes, and work in existing warehouses without any fixed navigation markers.

Marker-based navigation (QR codes or visual markers)

Robots can follow predefined paths by reading QR codes or visual markers placed on the floor. This approach is reliable but requires installing the markers and maintaining them to make sure they are always clean and readable.

Magnetic tape

Older systems guide robots along fixed routes using magnetic tape or embedded markers. These systems are stable but inflexible, since path changes require physical floor modifications.

In practice, SLAM-based navigation is increasingly preferred for modern, scalable warehouses, while marker-based and magnetic tape are mainly used by older technologies.

What are mobile manipulators?

Mobile manipulators are robots that combine a mobile platform with a robotic arm and vision system. Unlike stationary robotic arms, they can move through an environment while physically interacting with objects when necessary. This allows them to perform manipulation tasks such as picking, placing, or handling items across multiple locations rather than at one fixed workstation.

In warehouses, mobile manipulators navigate aisles, locate storage totes or shelves, identify individual SKUs, and pick items directly into order containers. Items that cannot be reliably picked are routed to human-assisted stations.

In addition, they can also be used for sortation, stock replenishment, tote consolidation and transportation. This approach automates item-level picking, the most labor-intensive part of fulfillment, while remaining flexible enough to operate in existing warehouse layouts.

Can mobile manipulators be used for order picking?

Yes. Some mobile manipulators, like Brightpick Autopicker, are specifically designed for item-level order picking in warehouses. They navigate aisles, retrieve storage totes, identify individual SKUs, and use robotic arms to pick items directly into order containers.

In practice, mobile manipulators handle the repetitive, high-volume portion of picking, while relying on humans-in-the-loop for occasional edge cases. For example, items that are irregular, fragile, or difficult to grasp are typically routed to Goods-to-Person stations. People also continue to play key roles in quality checks, exception handling, system oversight, and maintenance.

This hybrid model delivers high automation in real operations, with mobile manipulators handling the most labor-intensive work while humans manage edge cases and oversight, resulting in an efficient and robust system.

How do mobile manipulator robots pick individual items?

Mobile manipulators use Physical AI and machine vision to pick individual items.

When a robot arrives at a storage location:

- Cameras scan the tote or shelf

- AI models detect individual items based on shape, texture, and depth

- The software calculates the best grasp point

- The gripper picks the item using real-time force feedback

If an item cannot be safely picked due to packaging, reflectivity, or variability, the robot automatically routes it to a human-assisted picking station.

How do AMRs know what tasks to perform in warehouses?

Tasks assignment for individual AMRs is handled by the warehouse execution system.

The system evaluates:

- Order urgency

- Carrier cutoff times

- Current robot availability

- Tote locations

- Inventory availability

- Battery status

Based on this, the software continuously reprioritizes tasks and assigns robots to the most time-sensitive work first. This decision-making happens constantly in real time.

How to avoid AMRs causing traffic jams?

AMRs avoid traffic jams by coordinating their movements through fleet management software.

Most systems use a central controller that assigns tasks, manages priorities, and plans routes so robots do not all choose the same paths at the same time. Warehouses are often divided into zones or intersections with simple right-of-way rules, which prevents robots from blocking each other in narrow aisles or busy areas.

Robots also rely on real-time sensors to detect people, forklifts, or unexpected obstacles. When something changes, they slow down, reroute, or pause without disrupting the rest of the fleet.

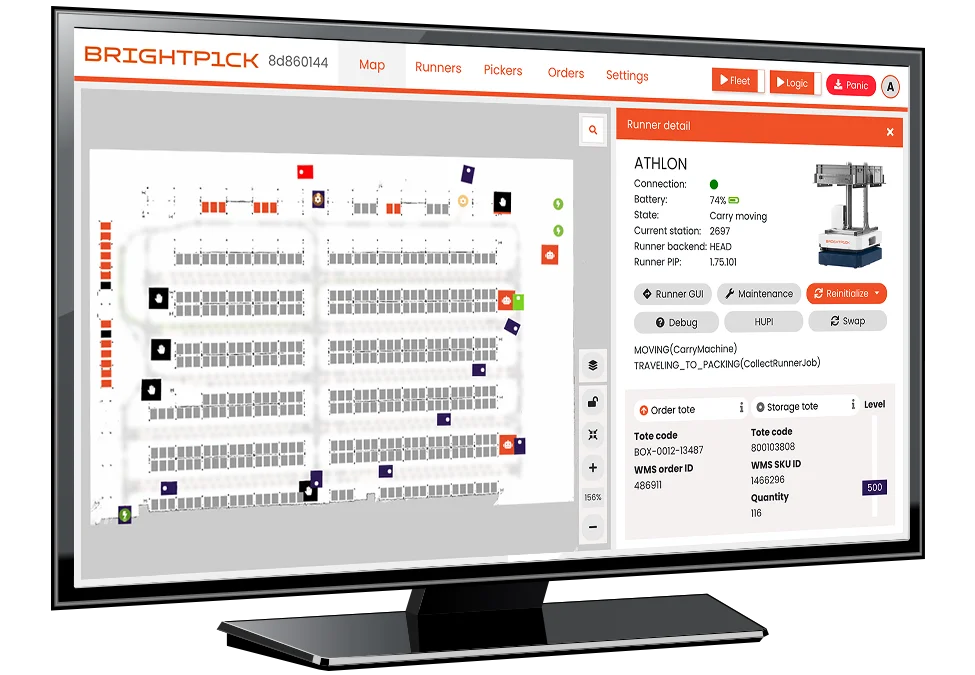

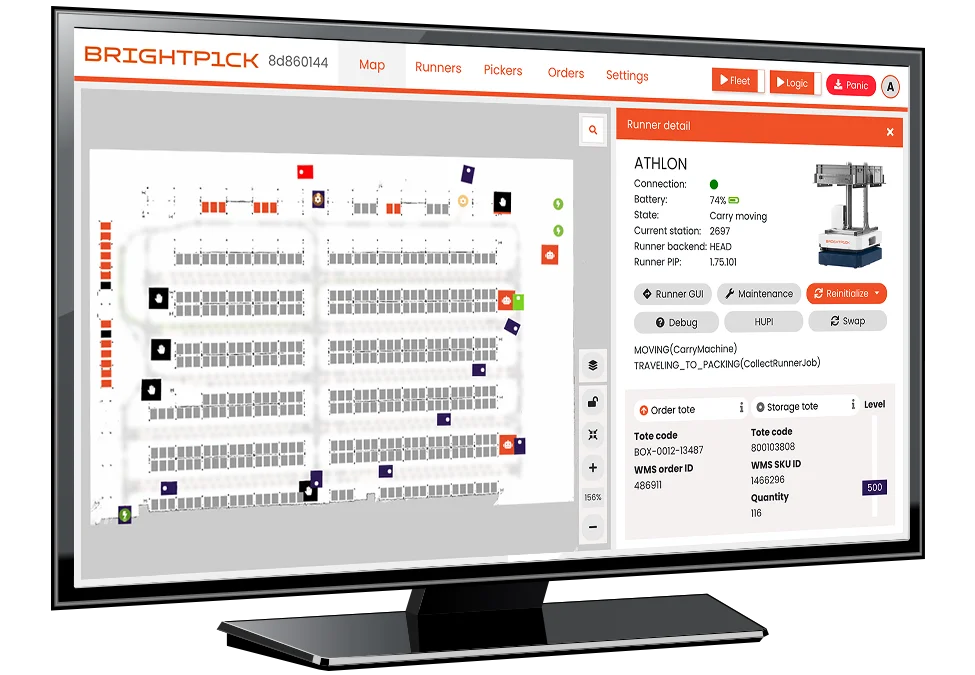

More advanced systems like Brightpick Intuition go a step further by predicting robot movements ahead of time. Instead of reacting only when congestion happens, the software plans routes based on where every robot is expected to be in the future and assigns non-conflicting paths upfront. This proactive coordination keeps traffic flowing smoothly even in dense, high-throughput operations.

In practice, the best results come from combining centralized coordination, simple traffic rules, and real-time obstacle avoidance, ensuring robots move efficiently without creating bottlenecks.

How do AMRs know where inventory is stored in the warehouse?

AMRs do not track inventory on their own. Inventory location is managed by the warehouse management or execution system (WMS or WES), which is always synchronized with robot activity.

When a robot removes a tote, picks an item, or replenishes new inventory into storage, the software updates:

- Exact SKU location

- Available quantity

- Tote ID

- Timestamp of movement

This creates a live digital inventory map with far higher accuracy than manual scanning, which is why automated warehouses typically achieve much higher inventory accuracy compared to manual operations.

Do AMRs utilize dynamic slotting?

It depends on the type of AMR and the software controlling the system.

Dynamic slotting is mainly used in tote-based AMR systems where inventory is stored in movable totes or containers. In these systems, the warehouse execution software tracks which products are picked most often and automatically adjusts where they are stored.

For example, popular SKUs are automatically moved closer to Goods-to-Person or packout stations, while slow-moving items are pushed deeper into storage.

This reduces travel distance during peak picking hours without requiring any physical reconfiguration by warehouse staff.

How difficult is it to install AMRs in existing warehouses?

Almost any automation can be installed in an existing warehouse, but the effort, cost, and disruption vary widely. Some systems require major changes such as floor grinding, fixed infrastructure, safety fencing, or long installation downtime. Others are designed to work with what is already there.

AMRs that are typically the easiest to deploy in brownfield warehouses because they:

- Are fully mobile and not dependent on fixed conveyors or rails

- Tolerate uneven or imperfect flooring

- Operate safely alongside people without requiring safety fencing

- Work with standard shelving and totes instead of custom infrastructure

- Use vision-based / LiDAR navigation rather than fixed guides such as grids, QR codes, or floor markers

Systems designed this way, including solutions like Brightpick, can often be installed in weeks and expanded gradually as volumes grow, without shutting down the operation or rebuilding the facility.

Do AMRs require safety fencing?

Many AMRs do not require safety fencing. Robots designed for shared environments can operate safely alongside people by relying on safety sensors. These robots continuously detect humans and automatically slow down or stop when someone enters their safety zone.

In some cases, fencing or physical separation is required. This is typically true for AMRs that move very heavy loads, operate at higher speeds, or rely on simpler navigation and safety systems. Physical barriers reduce risk in these scenarios.

A common middle ground is partial separation. Many warehouses avoid full fencing but use marked robot lanes, controlled crossings, speed limits, and clear traffic rules to safely manage human-robot interaction.

In short, fencing is not inherent to AMRs. It is determined by risk assessment, robot capability, and the operating environment.

How much human supervision do AMRs require?

AMRs significantly reduce labor needs, but they do not eliminate humans entirely. Human involvement typically falls into two distinct areas.

Humans supporting fulfillment tasks:

People are still needed for activities that are difficult or inefficient to automate, such as Goods-to-Person picking for complex items, decanting inbound pallets into totes, handling irregular or fragile products, and resolving operational exceptions. In these roles, humans support the robotic workflow.

Humans supporting technical operations:

Robot fleets are monitored through software dashboards that track throughput, battery status, traffic flow, error events, and pick success rates. Most troubleshooting and optimization is handled remotely by the vendor’s customer support or internal IT teams. On-site technical intervention is typically limited to mechanical issues, planned maintenance, or rare failures.

Overall, AMRs shift human effort away from constant manual work toward targeted support and oversight.

How reliable are AMRs for order fulfillment?

AMR reliability comes from system design. Before deployment, most vendors use simulations based on real order data to validate throughput, traffic flow, and charging behavior. This reduces risk and helps size the system correctly.

More importantly, modern AMR systems are designed without single points of failure. Robots operate independently, so one robot going offline does not stop the rest of the fleet. Software continuously reroutes work around unavailable robots or blocked areas.

For mobile picking robots, reliability is further improved through built-in fallback workflows. If a robot cannot pick a specific item, it can automatically route the tote to a Goods-to-Person station instead of halting the process. This ensures fulfillment continues even when edge cases occur.

Simulation, fleet-level redundancy, and human-assisted fallbacks work together to ensure AMR systems perform consistently in live warehouse operations.

About Brightpick

Brightpick is a leader in AI-powered robotic solutions for warehouses. The company’s multi-purpose AI robots enable warehouses of any size to fully automate order picking, buffering, consolidation, dispatch, and stock replenishment. The award-winning Brightpick solution takes just weeks to deploy and allows companies to keep their warehouse labor to a minimum. With offices in the US and Europe, Brightpick has more than 250 employees and hundreds of AI robots deployed with customers.