PERFORMANCE

Maximum labor savings

Brightpick robots don’t just move goods from point A to B. They also robotically pick, buffer and consolidate, delivering maximum labor and cost savings for your operation.

| ||

|---|---|---|

| Automated storage and retrieval | ||

| Automated putaway | ||

| Robotic picking | ||

| Automated order buffer | ||

| Automated order consolidation |

Performance

Higher throughput and faster picking

Brightpick boosts throughput during peak hours and maintains consistent performance all day by minimizing robot travel distances with in-aisle robotic picking.

| ||

|---|---|---|

| Throughput | High (distributed robotic picking, no congestion) | Low-to-medium (lots of congestion at picking stations) |

| Overnight picking | Yes (autonomous robotic picking and order buffering) | No |

| Density | High | High |

| Maintainability | Good (all parts easily accessible) | Average (may require pausing system) |

| Robots-as-a-Service | Yes | No |

| Single point of failure | No | No |

Pricing

Flexible pricing models

Brightpick is available through Robots-as-a-Service (RaaS), starting from just $1,990 per robot / per month.

RaaS transforms warehouse automation from a large upfront capital investment into a manageable monthly operating cost, which reduces financial risk, simplifies budgeting, and delivers immediate ROI.

Alternatively, the Brightpick solution is also available through a standard CapEx purchase.

Learn moreinstallation

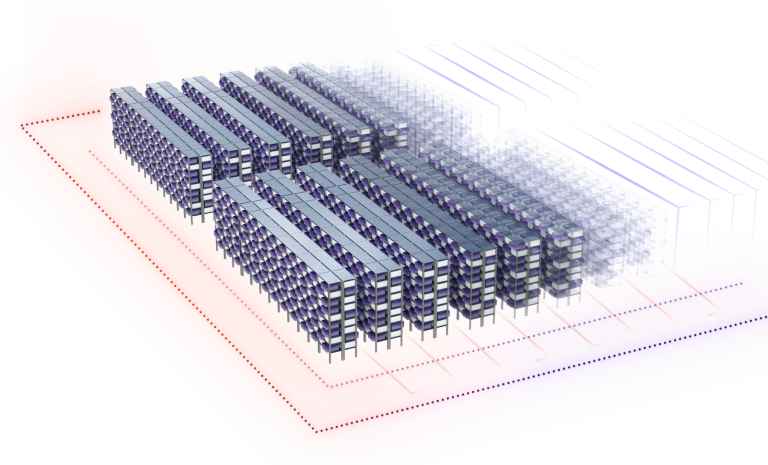

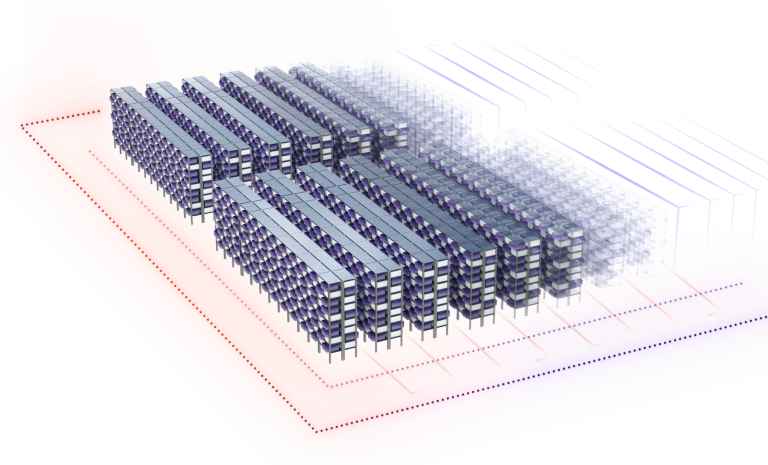

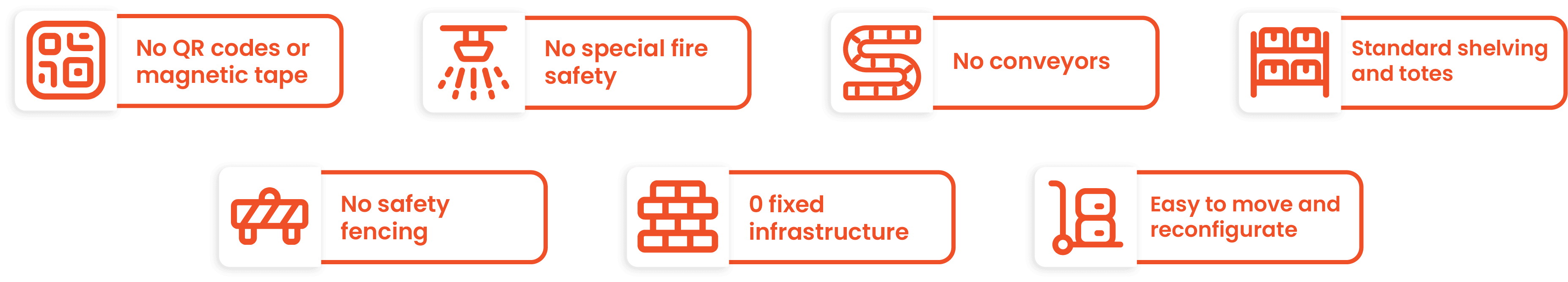

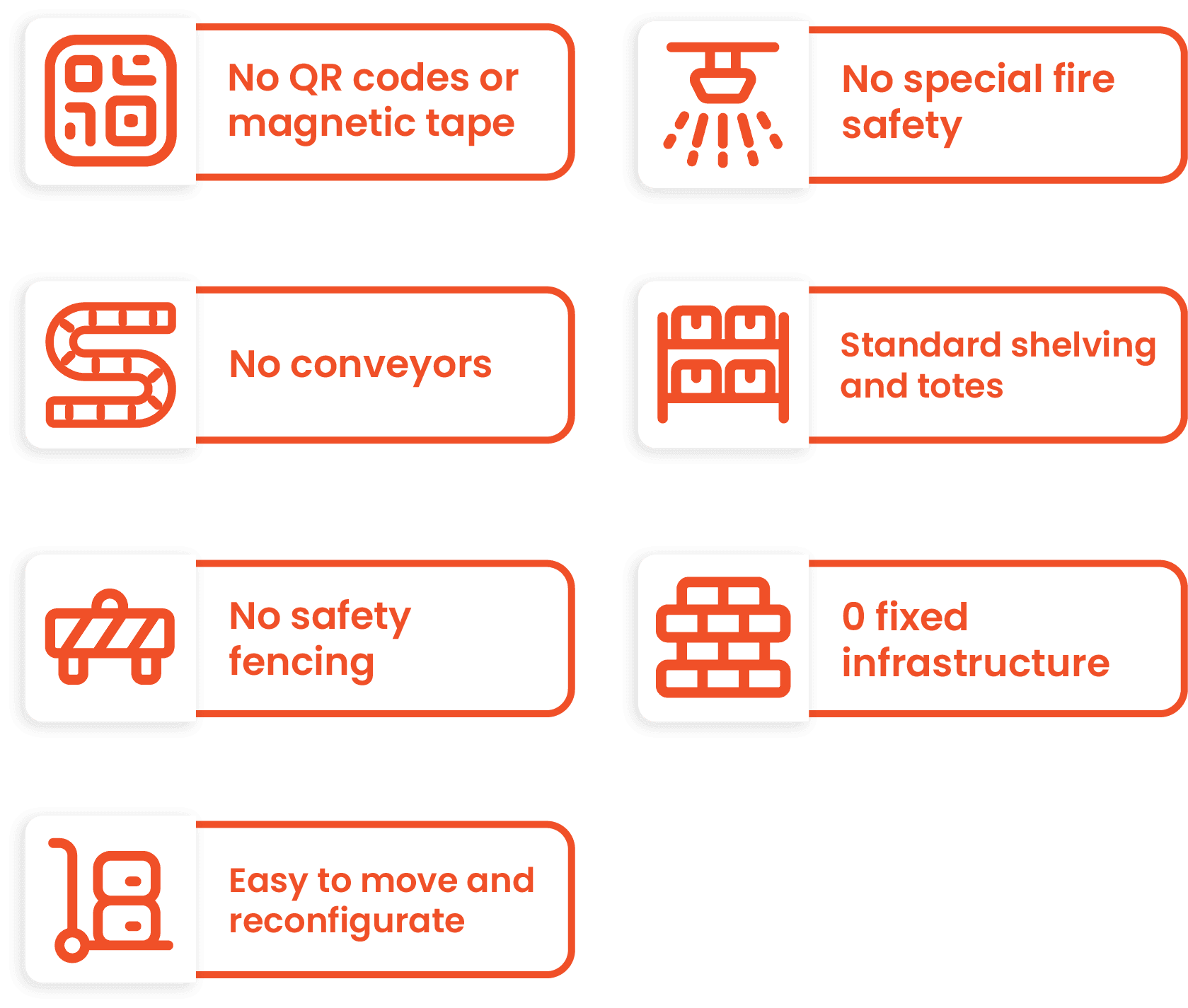

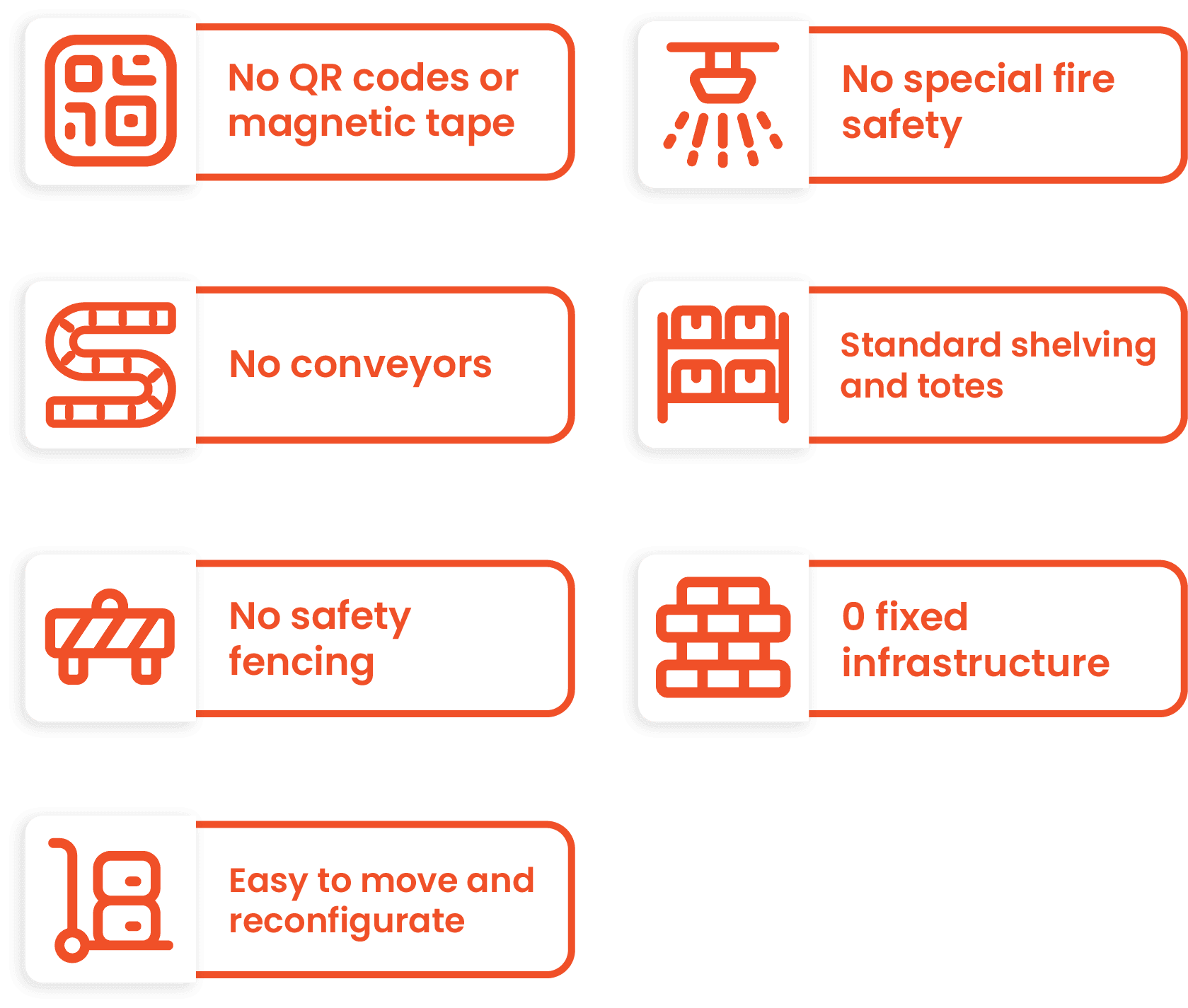

Easy to install and scale

Brightpick robots work with standard shelving and totes and require no fixed infrastructure. This enables fast deployment and easy integration with any warehouse environment, including existing warehouses and mezzanines.

What our customers say

Virtual demo

Watch our virtual demo of Brightpick Autopicker

Get Brightpick pricing & ROI

Whitepaper includes:

- Suitability (is Brightpick the right solution for you?)

- Pricing (transparent cost breakdown)

- ROI and savings (analysis of financial benefits)

- Solution design (detailed breakdown of the Brightpick system)

- Implementation timeline (step-by-step process to go live)

Frequently Asked Questions

-

What is the main difference between Brightpick and Geek+?

Both Brightpick and Geek+ use autonomous mobile robots (AMRs) to store and retrieve totes and feed Goods-to-Person (G2P) picking stations.

Brightpick robots go further by robotically picking items in-aisle (not only at G2P stations), and by automating order buffering, consolidation, and sequencing – minimizing human touches between storage and dispatch.

-

Is Brightpick a good alternative to GeekPlus?

Brightpick is a strong fit for teams prioritizing labor and cost savings, higher throughput, and scalable automation. Geek+ is well-suited for operations focused on G2P throughput and storage density with stable inventory and production profiles.

-

Does Brightpick or Geek+ provide higher labor savings?

Goods-to-Person solutions like Geek+ still require people at pick stations. Brightpick can robotically pick in-aisle and only use G2P stations when needed, typically enabling higher labor savings and throughput. Actual results depend on SKU mix, order profiles, and workflows.

-

Does Brightpick and Geek+ offer Robots-as-a-Service?

Brightpick offers its solution via Robots-as-a-Service (RaaS) as well as CapEx. Geek+ is typically only available via CapEx.

-

Where are Brightpick and Geek+ robots manufactured?

Brightpick robots are designed and manufactured in Slovakia (EU). Geek+ robots are manufactured in China.

-

How do picking rates compare between Brightpick and GeekPlus?

Both Brightpick and Geek+ support a range of G2P station throughputs ranging from 100 to 500+ tote presentations/hour depending on configuration. Brightpick also adds in-aisle robotic picking capacity, which can increase total system throughput beyond G2P picking alone.

-

Can Brightpick eliminate manual picking entirely?

It depends on the types of SKUs being handled. In some applications, such as pharmaceuticals, Brightpick Autopickers can pick 100% of SKUs and fully automate the process. In other cases, such as general merchandise, a small number of human pickers may still be required at Goods-to-Person stations.